Prediction of chemical heterogeneities and microstructure in solidified products

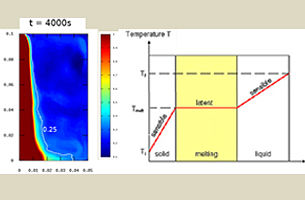

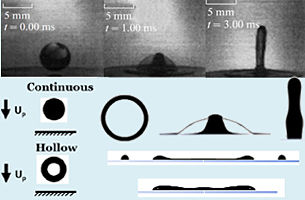

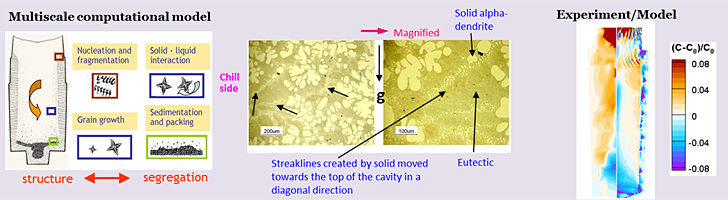

In this area, the multiscale phenomena of microstructure and chemical compositions formation in solidification processing (casting, welding) are studied, which comprehensively combines the coupled macroscopic transport phenomena of grain motion, fluid dynamics, heat and mass transfer, meso scale phenomena of flow instabilities, and microscopic phenomena of nucleation, grain growth and grain morphology evolution. Thermal spray coating using porous and hollow powder particles is being studied. The focus is to improve the understanding of the thermo- and hydrodynamic phenomena related to hollow droplets and porous particles impact on substrates. Development of thermal energy storage systems based on liquid-solid phase change principle, and study of dynamics of ice formation in ice generating tank using computational technique are also performed.

Research Areas

Solidification processing, thermal spray coating, and solid-liquid phase change energy systems.

Research Laboratories:

Manufacturing Science Laboratory

Associated Faculty

Arvind Kumar, PhD (IISc Bangalore): Manufacturing processes (casting, welding, layered and micro manufacturing); Heat transfer, CFD; Solid-Liquid phase change (Melting/solidification); Laser/plasma surface coating technologies; Phase change energy technologies