Vibration and Control Laboratory

Address:

NL 102

Overview:

This laboratory is mainly focused towards the experiments in the field of Vibration Analysis of Continuous Systems, Vibration Control by the use of various types of tuned mass damping, Provide familiarity to a wide range of sensors, Classical Control of Various first and second order systems.

Relevant Information:

The laboratory manual is available here.

Equipment:

-

Low Frequency Vibration Shaker

-

Vibration Transmissibility Measurement System

-

Vibration Control of 3D Frame Structure

-

Generic Platform for Vibration Analysis of Beams with Different Boundary Conditions

-

Universal Vibration Testing machine

-

Multi-sensor Test Bench

-

Temperature Control system using PID

-

Magnetic Levitation Control System

Experiments:

-

Study of a beat phenomenon of a coupled pendulum

-

Determination of effective radius of gyration of an irregular body through torsional oscillation of trifilar suspension

-

Determinations of natural frequencies of beams under simply supported and cantilever boundary conditions

-

Study of dynamic vibration absorber

-

DC motor speed control with various sensors

-

Measurement of linear displacement by potentiometer

-

Speed torque characteristics of DC servomotor

-

Balancing of ball and beam system through PID control

-

Active vibration control

Faculty: Dr. Bishakh Bhattacharya

Staff: Mr. Mohasin, Mr. R. K. Singh, Mr. Gynendra Tripathi

Contact Person: Dr. Bishakh Bhattacharya/Mr. R. K. Singh

|

|

|

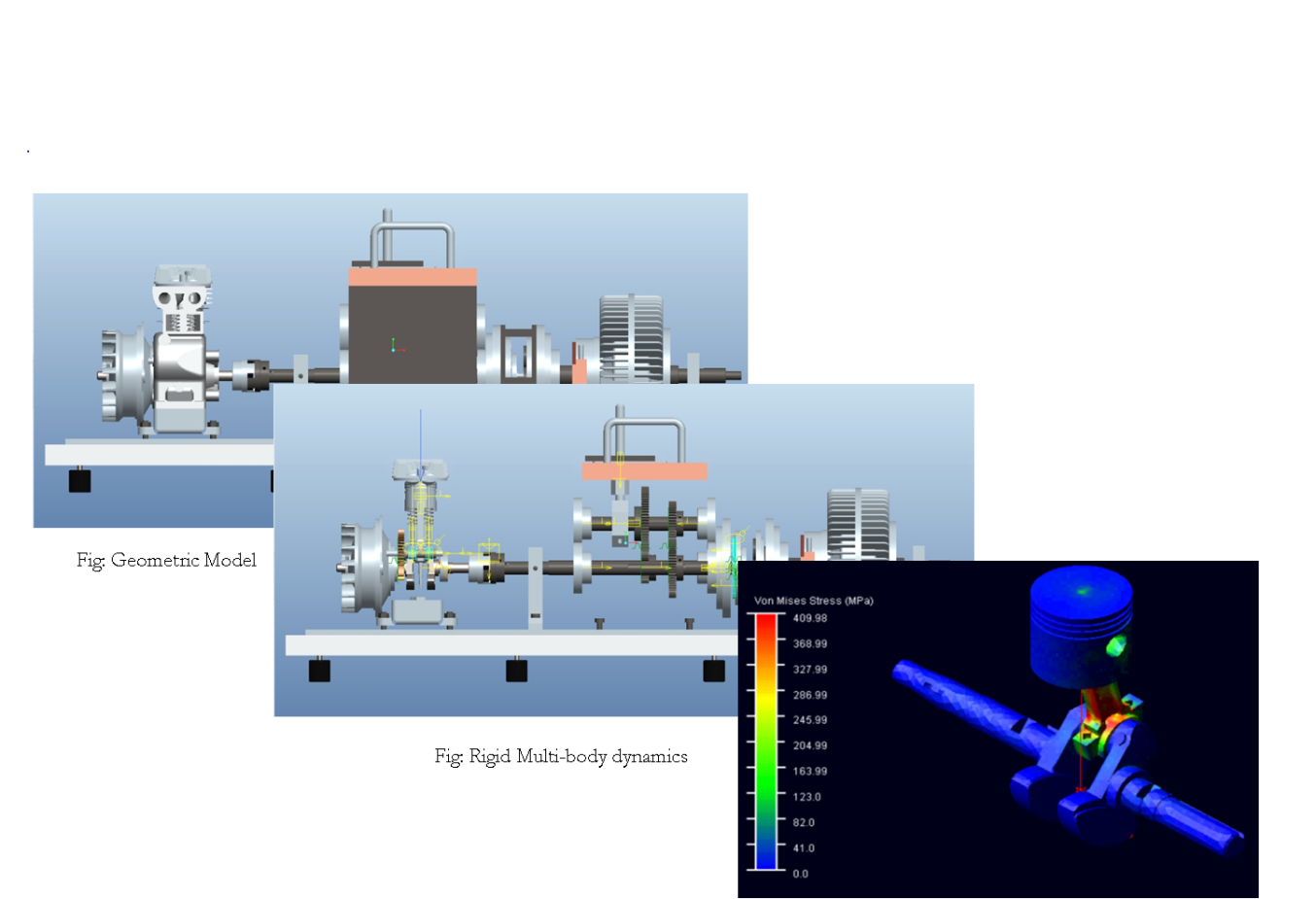

Virtual Rig of the Engine

|

| |

|

|

|

|

|

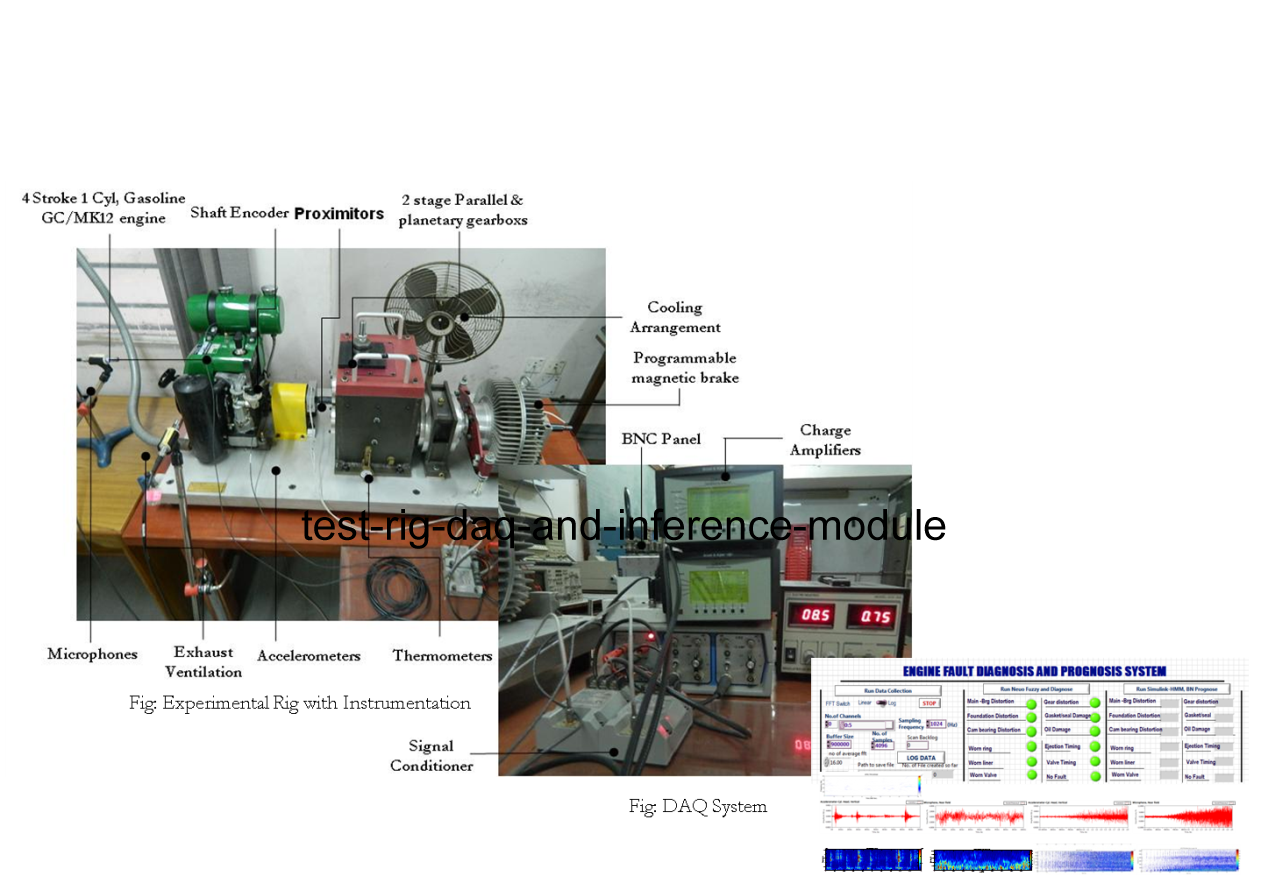

Test Rig, DAQ and Inference Module

|