Fluid Mechanics Laboratory

Address:

3rd floor NL-1

Overview:

This lab is run in conjunction with the theory course ME 231 (Fluid Mechanics). It is an introductory course where flow behaviour, fluid forces and analysis tools are introduced. The goals of the experiments include determination of forces generated when fluid flow takes place over a solid object, applications of the control volume approach, demonstration of the momentum and energy equations, viscosity measurement and engineering correlations. Intricate flow phenomena such as separations and transition to turbulence are demonstrated. Experimental setups such as flow through a tube, flow over a flat plate, wind tunnel, smoke tunnel and viscometer are made available to the students. The lab experiments utilize U-tube manometer and digital manometer, a hot-wire anemometer system and data acquisition. The lab runs closely with the lectures in such a way that experiments support the text covered in the class room.

Equipment:

Experiments:

-

Jet impact on flat and curved surfaces

-

Measurement of drag on a circular cylinder in high Reynolds number flow

-

Energy loss measurements in subcritical and supercritical open channel flow

-

Measurement of fluid viscosity

-

Determination of friction factor as a function of Reynolds number in pipe flow

-

Studying laminar-turbulent transition for flow in a tube

-

Boundary layer flow over a flat plate

-

Pressure distribution around a circular cylinder in high Reynolds number flow

Relevant Information:

The laboratory manual is available here.

The laboratory provides training to undergraduate and graduate students in flow measurements. It boasts of a considerable and diverse collection of imaging equipment, many of them developed within the laboratory itself. The areas of research include flow imaging, control, jets and wakes, micro-scale transport, and interfacial fluid dynamics. It has good computational facilities as well. A large number of Master’s and doctoral students have graduated over the years and flourish professionally around the world. The faculty has collaborated with organizations such as DRDL Hyderabad, SSPL, New Delhi, BARC Mumbai, RRCAT Indore, IGCAR Kalpakkam within the country. International partners include ETH Zurich, Kyoto University, Japan, and University of Minnesota, USA. Recently, the faculty has started collaborative projects with the private industry in solar energy, biomedical equipment, and diamond characterization.

|

|

|

|

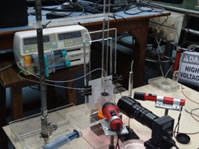

An undergraduate laboratory in progress

|

A wind tunnel experiment

|

| |

|

|

|

|

|

Open channel flow

|

|

|

|

Sub-critical flow

|

|

|

|

Reynolds experiment

|

Impact of jet apparatus

|

Super-critical flow

|

Sponsored Projects

-

SYNTHETIC JET ACTUATOR FOR DRAG REDUCTION OF UNDERWATER VEHICLES

-

LOCK-IN-THERMOGRAPHY FOR SOLAR CELL AND MODULE CHARACTERIZATION

-

Thermal striping study in a fast breeder reactor: eddies transport using combined PIV/ LIF and Schlieren techniques

-

A predictive model of aneurysm development in an arterial bifurcation

-

Micro-holographic particle image velocimetry development for biomedical and MEMS application

-

GENERATION OF SOLAR HYDROGEN

-

Development of a General Purpose CFD Solver over a Hybrid Unstructured Grid

-

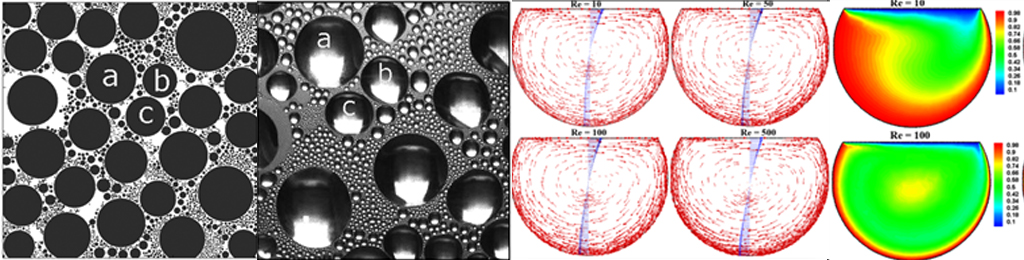

STATICS AND DYNAMICS OF MICRO DROPLETS FORMED ON TEXTURED SURFACES DURING CONDENSATION

-

QUANTITATIVE ANALYSIS OF IN VIVO MAGNETIC RESONANCE IMAGING DATA FOR DIAGNOSTICS OF VASCULAR DISEASES SUPPORTED BY CFD SIMULATION

-

EXPERIMENTS IN ACTIVE CONTROL OF BLUFF BODY DRAG USING SCHLIEREN VELOCIMETRY TECHNIQUE

Patents

-

Enhancing blood flow images using computational fluid dynamics.

-

Functional flow generator for multi-drug delivery system.

-

Non-invasive technique for evaluation of flow rates and identification of vascular deformation.

-

Water purification system using an enhanced solar still.

-

Light streak imaging technique for determining mass diffusivity in a binary diffusion process.

|

|

|

|

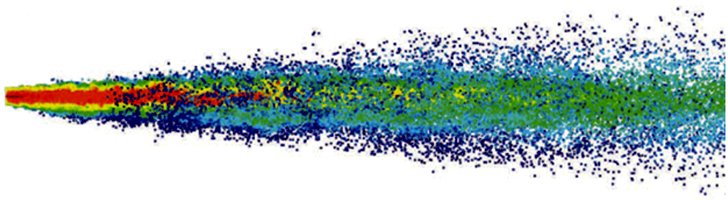

Colour schlieren

|

Mach-Zehnder interferometry

|

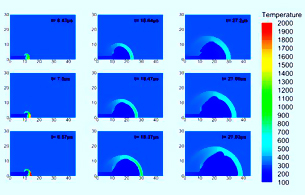

Liquid crystal thermography

|

|

|

|

|

Schlieren and shadowgraph

|

Particle image velocimetry

|

Enhanced solar still

|

|

|

|

|

Electro-atomization facility

|

Holograph and micro PIV

|

Particle tracking velocimetry

|

Faculty: Dr K Muralidhar, Dr P K Panigrahi, Dr. Arun K. Saha, Dr M K Das, Dr. S. Khandekar, Dr Anirban Guha

Staff: Manoj Sharma

Contact Person:

Dr M. Sharma

Room: NL 303

Phone: 4928

Email :

This email address is being protected from spambots. You need JavaScript enabled to view it.