| |

Manufacturing Science Lab

Teaching Laboratory

ME 361A: Manufacturing Technology

Overview:

Objective of this course is to give a broad understanding of conventional and non-conventional machining processes with an emphasis on the characterization techniques. This course also familiarizes students with the scientific principles governing various machining processes.

Equipments

- On Lathe- Lab VIEW Software, Three-component piezo-crystal type dynamometer make Kistler, NI DAQ Card, Microbalance, Dinolite USB Microscope, Vernier Calliper e.t.c.

- On Grinding- Lab VIEW Software, Three-component piezo-crystal type dynamometer make Kistler, NI DAQ Card, Microbalance, Dinolite USB Microscope, Portable Surface Roughness Measuring Instrument etc.

- On EDM – Electronica ZNC EDM Machine, Microbalance, Shadowgraph/ USB Microscope, Micrometer, Stopwatch, etc.

- On Hydraulic Press- USB Microscope, Load Cell, Lab VIEW Software, NI DAQ Card, Vernier Calliper, Proving Ring etc.

- On Microchannels fabrication- Microbalance, USB Microscope, Dessicator, vacuum pump, Furnace temperature upto 400 degree centigrade etc.

- On Milling- Multi-component dynamometer make Kistler, Labview software, NI DAQ Card, Dinolite USB Microscope, Vernier Calliper, Microbalance etc.

Experiments:

- To measure the cutting force, tool temperature and shear angle during orthogonal cutting (on Lathe).

- To study the effects of grinding variables on grinding forces, specific energy and surface finish.

- To study the EDM machine and determine material removal rate and tool wear rate during machining of EN8 steel.

- To draw a cup by cup drawing process and measure the drawing force on hydraulic press.

- To fabricate micro channels through micro Replication double inversion technique.

- Investigation of wear and cutting processes (Fx, Fy, Fz and Mz) near the tool age during milling and drilling by Rotating 4-Component Dynamometer (RCD) on EMCO Mill concept 250.

- To obtain the measurement of a given component using coordinate measuring machine (CMM).

- To fabricate micro channel through epilog laser fiber mark fusion engraving machine.

- To measure the axial force, with tool speed for different diameters, if the feed is constant on HMT Radial Drill Machine.

- To obtain the measurement of roundness of a given component using Out of roundness measuring machine (Mitutoyo, Japan)

- To measure the cutting force, shear angle during orthogonal cutting, cnc programming (Absolute/Incremental) and operations on flat bed Simple Turn5075 ACE Designer CNC Lathe Machine.

- To study the various features of surface roughness measuring instrument also measure the parameters of the specimen.

- To study the integrated multi process (µ-milling, µ-turning, µ -drilling, µ-EDM, µ-ECM, µ-wire cut, µ-EDG) on micromachining machine DT-110.

|

Processing Equipment:

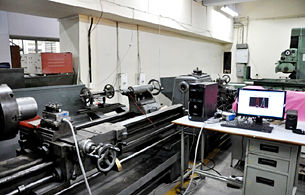

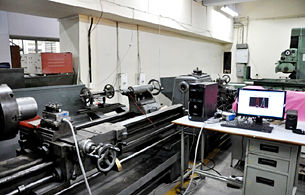

HMT LB-25 Centre Lathe:

Specification:

HMT LB-25 LATHE 500mm SWING x 2000mm BETWEEN CENTRES. 18 SPEEDS 32-1600 RPM. 52mm SPINDLE BORE WITH 3 JAW CHUCK, 4 JAW CHUCK, FACE PLATE, MULTIFIX QUICK CHANGE TOOLPOST.

|

|

|

Processing Equipment:

Horizontal Surface Grinding Machine

Make: HMT

Model: SFW1

Magnetic Chuck Size: 1000mm x 300mm

Accuracy: 2 μm

Table speed: 2.5, 5, 10, 15, 20, 25 (m/min)

RPM: 1500

|

|

|

Processing Equipment:

Electronica R50# ZNC

Work tank : 800 x 500 x 350 mm

Work table size: X Y Z : 300 x 250 x 200 mm

Programmable Z axis control, manually operated x and y axis.

Accuracy: 5µ

99 programs, 50 steps per program

Max. working current: 50A

Gap voltage: 100-270V

Max. Stock removal (cu-steel): 300(cu.mm/min)

Best surface finish: 0.5µ CLA

Electrode wear: 0.3-20%

|

|

|

Processing Equipment:

SPECIFICATION:

Make : Fluid Power

Type : Hydraulic

Bed Size : 500 mm x 500 mm

RAM Dia. : 12 mm"

Capacity : 10 T

|

|

|

Processing Equipment:

SPECIFICATION:

Model/Make: EMCO Concept Mill 250

Max Speed: 10,000RPM, Power 7KW

20 Station Tool Drum with directional logic

Travel- X350mm, Y250mm, Z300mm

Clamping Surface- 500x300mm

PC Controlled CNC –Machining center with Interchangeable control

EMCO Software Win NC

SINUMERIK 810/840D machine license (32bit)

Software EMCO 3D View

4th Axis- NC Dividing Head WALTER TANI 80 NEG

5th Axes- Turntable DSE25 èSpindle Speed A axis 15rpm; Spindle Speed B axis 3rpm; Size- X/Y/Z = 520/260/150; Swiveling Height =80MM; Swiveling Area of 4th Axis = Max. ±91o

ESPRIT CAM Software è Powerful Spectrum Programming for

2-5 Axis Milling,

2-22 Axis Turning, 2-5 Axis Wire EDM,

Multitasking Mill Turn Machining,

Swiss Turn and B-Axis Machine Tools High Speed 3 and 5- Axes Machining.

|

|

|

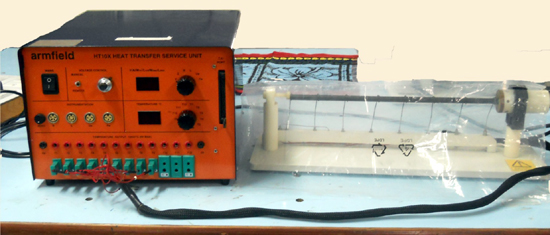

Characterization Equipment:

Coordinate Measuring Machine

Model: - Spectra 5.6.4. CNC

Scale Regulation = 0.5 μm

Machine accuracy = (± 2.5 + L/250) μm; (L: Standard length in mm)

Angular accuracy = 1” (One second)

Granite flatness = 2 micron per meter square

Granite grade = zero grade

Probing system = MS2DI

M/c version = CNC version

M/c working volume = X = 500 mm; Y = 600 mm; Z = 400 mm

Controller name = Renishaw UCC (Universal CMM Controller) lite-2 (U.K.)

|

|

|

Processing Equipment:

Epilog FiberMark Fusion

Size (W x D x H): 52.5" x 33.5" x 40.75"

(1334 x 851 x 1035 mm)

Engraving Area: 32" x 20"

(812 x 508 mm)

Focal Length (F-Theta Lens): 5" (127 mm)

Maximum Material Thickness: 11.25" (285 mm)

Laser Wattage 20, 30, or 50 watts

Laser Type: Solid State Pulsed Ytterbium Fiber Laser (air cooled)

Mode of Operation: Pulsed 20-80 kHZ.

|

|

| |

|

|

Processing Equipment:

Hindustan Radial Drill Machine

Specification:

Make : HMT

Model : RM61

Spindle Capacity : 60 mm

Arm Length : 1200mm

RPM : 40,56, 80, 112, 150, 220, 300, 440, 580,

850, 1160, 1700

|

|

|

Characterization Equipment:

Mitutoyo RA-116 Round Test

Specification:

• Measuring and analysis software package ROUNDPAK running under Windows operating system

• Air-bearing turntable for high precision, wear-free rotation

• Accepts workpieces up to ø17.32" (440mm) diameter

• Turntable loading 20 kgf maximum

• Measurable diameter ø11.02" (280mm)

• Measuring range ±1000μm

• Measuring height for outside/inside diameters: 11.02" (280mm) maximum

• Measuring depth inside 3.94" (100mm) maximum (with standard stylus)

• Traverse of R axis 6.5" (165mm)

• Large centering range ±.12" (±3mm)

• Large levelling range ±1°

|

|

|

Processing Equipment:

ACE MAKE FLAT BED CNC LATHE MACHINE MODEL SIMPLE TURN 5075 WITH FANUC Oi MATE –TD CONTROL

Specification:

Swing Over Bed: Ø500

Swing Over the cross slide: Ø220

Maximum Turning Length : 650mm

Distance between Centers: 750mm

Spindle speed: 0-4000rpm

Spindle Motor Power: 11/7.5KW

LINEAR TOOLING

X Axis: 300mm

Z Axis: 700mm

Tailstock Quill Travel 180mm

Quill Taper: MT-5

|

|

|

Characterization Equipment:

Surface Roughness Measuring Instrument Specification:

Model SJ–301, Make: Mitutoyo

Measuring range

Z-axis 350 μm

X-axis 12.5 mm

Drive Unit Measuring: 0.25 mm/s; 0.5 mm/s

Speed Returning: 1.0 mm/s

Standard Probe (178-395)

Measuring Method Induction method

Stylus Diamond Tip: Radius 2 μm

Measuring Force 0.75 mN

Parameters: Ra, Rq, Rz

Cut-off-Length: 0.08 mm, 0.25 mm, 0.8 mm,

2.5 mm, 8 mm

Sampling Length: x 1, x 3, x 5, x L

|

|

|

Processing Equipment:

Mikrotools DT-110

Specification:

Work Table: 440 X 320

X & Y Axis Travel: 350 X 270

Z Axis Travel : 320+300

Max weight of the work piece: 350 kg

Work tank: 800 X 480mm

Connected load: 2 KVA

Max matching current: 20 amp.

Machine Footprint: 950 X 770 X 1950

Accuracy: 0.1 μm (100nm).

|

|

|

Characterization Equipment:

Dino-Lite Premier USB Microscope

Specification:

Model: AM7013MZT4 Dino-Lite Premier

Interface: USB2.0

Resolution: 5Megapixel

Magnification Range: 20x-250x

Sensor: Color CMOS

Save Formats:

Image: BMP, GIF, PNG, MNG, TIF, TGA, PCX, WBMP, JP2, JPC, JPG, PGX, RAS, PNM DinoXcope: PNG, JPEG

Movie: WMV, FLV, SWF

DinoXcope: MOV

Polarizer and Measurement Function

|

|

| |

|

|

Characterization Equipment:

3-Component Dynamometer

Specification:

Dynamometer with handy size. Built-in charge amplifier with 4 measuring ranges switchable. Simple operation with control unit Type 5233A1.

Type 9257BA

External control unit for range selection and reset/operate. Signal output with 3 x BNC neg. and D-Sub 37-pin.

Type: piezo-crystal

Forces: Fx, Fy and Fz with four miniature

Range: Fx and Fy 500N to 5KN

Fz: 1KN to 10KN

|

|

|

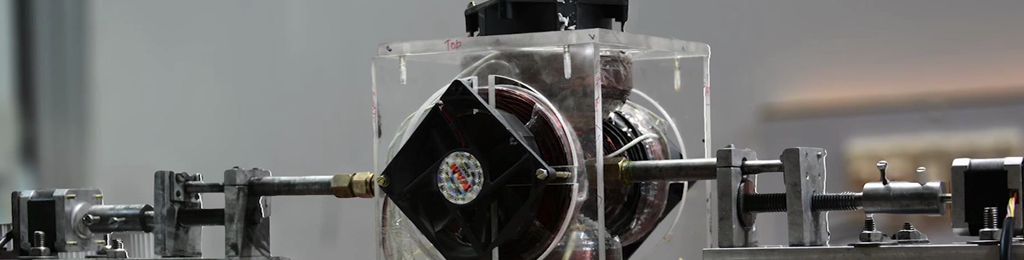

Characterization Equipment:

Rotating 4-Component Dynamometer (RCD)

Specification:

Make: KISTLER

Dynamometer Type 9123C

The dynamometer consists of a four component sensor fitted under high preload between a baseplate and top plate. The four components are measured practically without displacement.

Rotating 4-component dynamometer for measuring of cutting forces and torques on the rotating tool spindle. Transmission of measured data by telemetry hence without wear.

Speed 1/min max. 10 000

Range 1 FSO Fx, Fy kN –5 ... 5

–3 ... 3

Fz kN –20 ... 20

Mz Nm –200 ... 200

Range 2 FSO (switchable) Fx, Fy N –500 ... 500

Fz kN –2 ... 2

Mz Nm –20 ... 20

Sensitivity (Range 1) Fx, Fy mV/N ≈ 2

Fz mV/N ≈ 0,5

Mz mV/Nm ≈ 50

Forces: Fx, Fy, Fz and Mz

|

.jpg)

-2.jpg)

|

|

Characterization Equipment:

Column Load Cell

Specification:

Make: IPA

Model: FC074H0

Type: Stain gauge based

Capacity: 70Ton

Gauge Resistance: 350 ohms nominal

Exitation voltage: 10v DC

Sensitivity: 1.5mV/V

Safe overload: 150% of rated load.

Resolution: 50Kg

|

|

|

Characterization Equipment: Microbalance

Specification:

Make: CITIZEN

Model: CY204

Capacity x Resolution (g): 220 g x 0.0001 g

Repeatability: 0.0001 g

Linearity: 0.0002 g

Response Time: 2 - 3 seconds

Units: g, mg, ct, GN, mo, oz, dwt

Platform Dimensions: 3.5" diameter

Sensor Type: Electromagnetic Force Compensation

|

|

|

Characterization Equipment:

Proving Ring

Specification:

Make: HEICO

Model: PR-302

Capacity: 5KN

Dial Gauge: ASAHI

Calibrated in: Compression

|

|

|

Characterization Equipment:

Fluke Ti400 Infrared Camera

Specification:

Make: FLUKE USA

Model: TI-400

Temperature measurement range : -20 °C to +1200 °C

Temperature measurement accuracy: ± 2 °C

Image capture frequency: 9 Hz refresh rate or 60 Hz refresh rate depending upon model variation

Detector type: Focal Plane Array, uncooled microbolometer, 320 x 240 pixels

Thermal sensitivity (NETD): ≤ 0.05 °C at 30 °C target temp (50 mK)

Total pixels: 76800

Minimum focus distance: 15cm

|

|

Characterization Equipment:Anton Paar Physica MCR301

Specification:

|

Technical Data

|

Unit

|

MCR 302

|

|

Bearing

|

|

Air

|

|

EC motor

|

|

Yes

|

|

Maximum torque

|

mNm

|

200

|

|

Min. torque, rotation

|

nNm

|

1

|

|

Min. torque, oscillation

|

nNm

|

0.5

|

|

Angular deflection

(set value)

|

µrad

|

0.05 to ∞

|

|

Min. angular velocity

|

rad/s

|

10-9

|

|

Max. angular velocity

|

rad/s

|

314

|

|

Max. speed

|

1/min

|

3000

|

|

Min. angular frequency

|

rad/s

|

10-7

|

|

Max. angular frequency

|

rad/s

|

628

|

|

Normal force range

|

N

|

0.005-50

|

|

Normal force resolution

|

mN

|

0.5

|

|

Max. temperature range

|

°C

|

-150 to +1000

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

| |

|

| |

|

Characterization Equipment:

Nikon eclipse LV100 Industrial Microscope

Specification:

Model name: ECLIPSE LV100D

Magnification: 5x0.15, 10x0.30,

20x0.45, 50x0.80, 100x0.90 (LO plan fluor)

Optical system: CFI60 optical system

Illumination: Lamp ratings: 12 VDC, 50 W halogen lamp

Specified lamp: LV-HL50W 12V 50W halogen lamp

Specified lamp house: LV-LH50PC

Focusing mechanism: Stroke: 30 mm

Coarse focus knob: 14 mm/revolution

Fine focus knob: 0.1 mm/revolution

Eyepiece: 10x, field number: 22, 25

Operating environment: Temp: 0°C to +40°C

Relative humidity: 85% RH max.

Altitude: 2000 m max.

Pollution degree: Degree 2 |

|

Relevant Information (if any): Faculty: Dr. J. Ramkumar (Lab Coordinator) Staff: Mr. Sanjeev Kumar Verma, Mr. Atul Kumar Gangwar Contact Person: Mr. Sanjeev Kumar Verma Location: NL-1-115A Manufacturing Science Lab., ME, IIT Kanpur Phone: 0512-259-7923 Email:

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

.jpg)

-2.jpg)