ME659A

|

TRIBOLOGY OF MACHINING PROCESSES

|

Credits:

|

|

3L-0T-0L-0D (9 Credits)

|

|

|

Course contents:

Fundamentals of machining, Mechanics of metal cutting, Thermomechanical analysis, Chip formation, Basic tribo-interaction in machining, Governing factors at machining interfaces, Methods for predicting friction, Frictional regimes, Friction models, Special tribometry, Cutting tool wear, Wear modes and characterization, Wear models, Wear monitoring and control, Modern lubri-coolant methods, Sustainability aspects in machining, Influence of lubri-coolant method of machined surface integrity, Surface engineering, Development of modern cutting tools, Laser processing and coatings, Coating degradation mechanisms, Experimental techniques in machining, Wear map generation, Split tool, Quick stop method, Ballistic machining, Chip geometry control, Surface and sub-surface characterization, Formation and detection of adiabatic shear banding

Lecturewise Breakup (Based on 75 min per lecture)

I. Machining Science: A tribological perspective (6 Lectures)

-

Mechanics of metal cutting, Stresses and strains in machining, Thermal complexities, Thermomechanical modeling, Chip formation and its signature, Basic tribological interaction, Formation of machining tribo-pairs (macro and micro scale)

II. Friction in machining (6 Lectures)

-

Governing factors at various interfaces, Experimental methods and analytical techniques for predicting friction, Zorev’s friction model, Influence of machining parameters, Frictional regimes over tool rake/flank face/edge, Cutting edge and stagnation zone, Open and close tribometry tests

III. Cutting tool wear: Mechanism, characterization, and control (6 Lectures)

-

Types and mechanisms of tool wear, Edge dulling and wear, Plastic lowering of cutting edges, Machining parameters and Arrhenius wear equations, Basic and advanced methods for characterizing wear modes, Diffusion couple configurations, Material dependence on wear genesis and growth, Wear monitoring and control, Single and multi-sensor fusion-based wear monitoring

IV. Modern cooling and lubrication methods (5 Lectures)

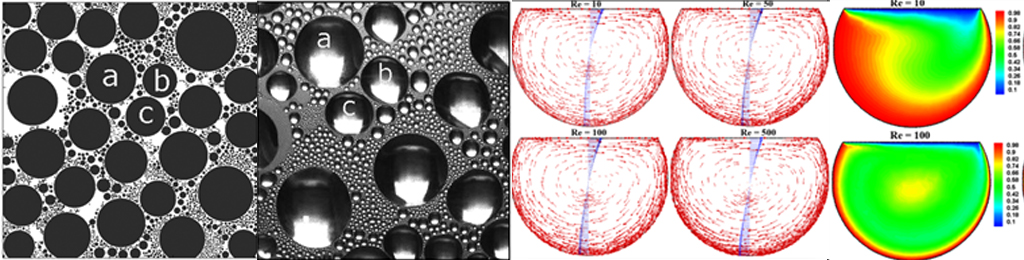

-

Capillary zone and fluid penetration, Sustainability of machining processes, Cryogenic machining, MQL/nMQL/Cryo-MQL, Hybrid cooling and lubrication, High-pressure jet cooling, Vortex tube and air cooling, Machined surface and sub-surface damages

V. Surface engineering for effective machining (6 Lecture)

-

Surface finish, Edge finish, PCE and SCE finish, fracture roughness, Cutting tool manufacturing and related secondary operations, Hard and soft coatings, Coated tools (architecture and selection), Coating degradation mechanisms, Methods of surface structuring, Laser surface processing, Micro blasting, Mechanisms for improved machining tribology, Combinatorial approaches for improved cutting

VI. Experimental techniques in machining (6 Lectures)

-

Split tool method, Wear map criteria for cutting, Quick stop method, Inverse identification, High heat-high strain rate tests, Chip geometry/shape analysis and control, Ballistic machining and chip formation, White layer and microcrack formation (in chip and work), RS depth profiling, finished surface damage analysis, Detection of ASB in ferrous and non-ferrous alloys

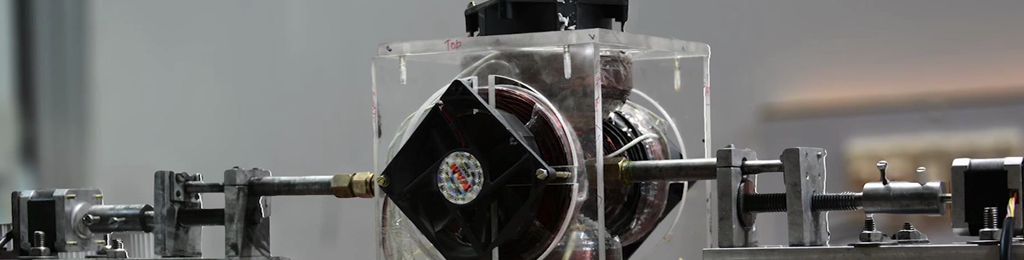

VII. Demonstrations (5 Lectures)

References:

-

Manufacturing Science, A. Ghosh, A.K. Mallik, Second Edition, EastWest Press, 2010, ISBN-978-8176710633

-

Introduction to Tribology, H. Tennekes and J. L. Lumley, MIT Press

-

Tribology: Friction and Wear of Engineering Materials, I. Hutchings, P. Shipway, Second Edition, Butterworth-Heinemann, 2017, ISBN: 978-0081009109

-

Introduction to Machining Science, G.K. Lal, Third Edition, New Age International publishers, 2007, ISBN: 978-8122421040

-

Fundamentals of Modern Manufacturing, M.P. Groover, Seventh Edition, Wiley, 2019, ISBN: 978-1119635697

|