|

|||||||||||||

|

|||||||||||||

|

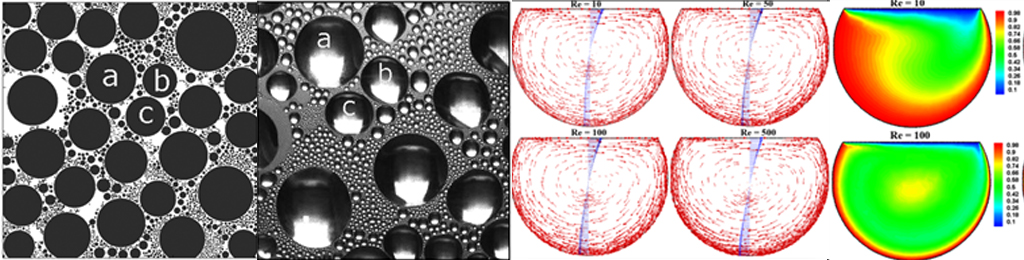

|||||||||||||

ObjectivesThe main objective of this course is to acquaint students with various manufacturing processes such as casting, joining, bulk deformation and additive manufacturing. The course includes design aspects, mechanistic analysis and defects associated with these processes. Course contentIntroduction to primary manufacturing processes and properties of materials; Casting and solidification of alloys: Mechanism; Analysis of cooling curve; Runner and gating system design; Riser design; Joining processes: Fusion welding mechanism; Heat flow and material transfer 12 mechanism; Microstructure formation; Welding defects and inspection; Bulk deformation processes: Brief review of plastic deformation and yield criteria; Mechanistic analysis of Forging, Rolling, Drawing and Forming processes including defects; Additive manufacturing processes: Mechanistic analysis of polymers, metals and ceramics based additive manufacturing processes. Total number of lectures: 26Lecturewise breakup1. Introduction and Manufacturing Properties of Materials : 1-2 Lectures 2. Casting : 6-8 Lectures

3. Joining: 4-5 Lectures

4. Bulk Deformation: 7-8 Lectures

5. Additive Manufacturing: 4-5 Lectures

Recommended books

Proposing instructors: Dr. V. Kumar, Dr. S. Mishra, Dr. K. Ramani, Dr. U. Roy, Dr. S. Mukhopadhyay, Dr. M. Law, Dr. A. Kumar, Dr. N. Sinha, Dr. S. Bhattacharya |

|||||||||||||