Address

Southern Laboratory-210

Overview

Heat transfer laboratory is an undergraduate teaching laboratory housing a handful of experimental setups pertaining to fundamental heat transfer problems and their applications. The experimental setups in this laboratory are a part of the curriculum for third-year undergraduate students undertaking the course “ME341A: Heat and Mass Transfer”. Listed below are the experiments performed by the enrolled students as part of their course:

Pin Fin Apparatus: This setup is designed to study the heat transfer in a pin fin. It consists of cylindrical fin fitted to the base in rectangular duct. A blower is provided on one side of duct to conduct experiments under forced convection heat transfer mode. Five thermocouples are embedded along the axis of the cylindrical fin at five different locations and one thermocouple placed in the air stream at the exit of the test section to measure the outlet air temperature. Digital Temperature Indicator is provided to read temperatures distribution along the fin. Test pipe is connected to the delivery side of the blower along with the Orifice to measure flow of air through the pipe. A heater heats one end of fin and heat flows to another end. Heat input to the heater is given through variac. Students will be expected to develop the following skills/understanding upon the successful completion of this experiment:

- Determine the temperature distribution along the length of a pin fin and the average heat transfer coefficient for the fin under forced convection configuration

- Compute the effectiveness and efficiency of the pin fin

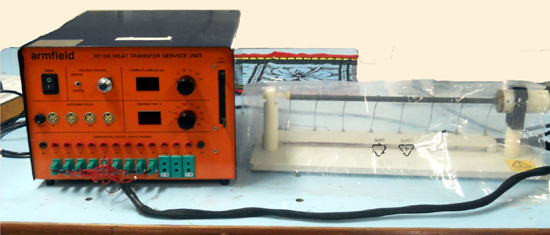

Heat transfer through extended surface: In this experiment heat transfer from the extended surface relies on natural convection and radiation. This experimental set up consists of HT15 extended surface heat transfer accessory alongside HT10X heat transfer service unit on a suitable bench. Power lead is connected from the HT15 to the HT10x heat transfer service unit. There are 9 thermocouples on the HT15 connected to the appropriate sockets on the front side of the service unit. Voltage controller, manual/remote switch, thermocouple selector and digital temperature indicator are provided on the front panel of the service unit. The following objectives are sought for by performing this experiment:

- Establish the temperature distribution along the length of a tip-insulated extended surface and compare with analytical predictions

- Compute the individual heat transfer coefficients over its periphery under the influence of both free convection and radiation heat transfer

- Determine the thermal conductivity of the rod material using the observed data and computed heat transfer coefficients

Measurement of emissivity: This experimental set up consists of two circular aluminium plates, plate one blackened by thick layer of lamp black to form the idealised black surfaces where as the plate 2 is the test plate whose emissivity is to be determined, identical in size and provided with heating coils at the bottom. The heat input to the heater is varied by separate dimmer stats and is measured by an ammeter and a voltmeter. Separate wires are connected to diametrically opposite points to get the average surface temperature and one thermo couple is placed in the enclosure to measure ambient temperature. The heater inputs to the two plates are dissipated by conduction, convection and radiation. The experimental set up designed in such a way that under steady state conditions the heat dissipated by conduction and convection in the same for the two plates.

Heat transfer by natural convection: The setup consists of a brass tube fitted in a rectangular duct in a vertical fashion. The duct is open at the top and bottom, and forms an enclosure and serves the purpose of undisturbed surrounding. One side of the duct is fitted with a transparent good quality Acrylic window for visualization. An electric heating element is kept in the vertical tube that in turns heats the tube surface. The heat is lost from the tube to the surrounding air by natural convection. The temperature of the vertical tube is measure by Temperature Sensors and displayed by a digital temperature Indicator with multi-channel switch. The heat input to the heater is measured by a ammeter and a Voltmeter and is varied by a variac. The tube surface is polished to minimize the radiation losses.

- Determine the heat transfer coefficient for heat loss via natural convection from a vertical, uniformly-heated (uniform heat flux) cylinder

- Compare the experimentally obtained heat transfer coefficient with that estimated using a suitable empirical correlation

Critical heat flux measurement apparatus: This experimental set up is designed to study the pool boiling phenomenon up to critical heat flux point. The apparatus consists of a cylindrical glass container housing the test heater ad a hater coil for the initial heating of the water. This heater coil and test heater connected to mains via dimmer stats. An ammeter is connected in series while a voltmeter across it to read the current and voltage, respectively. The glass container is kept on an iron stand which could be fixed on a platform. There is provision of illuminating the test heater wire with help of a lamp projecting light from behind the container. A computer is facilitated for observing formation of bubbles and to identify the different regimes of pool boiling phenomenon. The following things can be studied by performing this experiment.

- Obtain the value of critical heat flux for pool boiling of water under sub-cooled (varied degree of sub-cooling) and saturated conditions

- Compare the experimentally obtained critical heat flux at the saturation temperature with that obtained using Zuber’s correlation

Unsteady state heat transfer:

This experimental set up is used to observe unsteady state conduction of heat to the centre of a solid shape when a step change is applied to the temperature at the surface of the shape. This apparatus consists of a HT17 unsteady state heat transfer unit, a PC running windows with available USB socket and a HT10XC computer compatible heat transfer unit. The method of experiment is allowing solid shapes of different sizes, form and materials of construction to stabilise at room temperature and then dropped into a bath of hot water. The change in temperature at the centre of each shape is continuously logged using a PC connected to the HT10XC. The following objectives are pursued:

- Estimate the heat transfer coefficient for a transient heat transfer situation from an isothermal working fluid to solid blocks of varied shapes made of a specific material

- Determine the thermal conductivity of a material with the help of the known thermal conductivity and heat transfer coefficient for a similar shaped block but made of a different material

Thermocouple Calibration:

Thermocouple calibration is of paramount significance in obtaining accurate temperature measurements. In this experiment, Fluke's Field Metrology Well (FMW) – 9143 & Temperature scanner – 1586 A are used to calibrate in-house made J-type thermocouples for a range of temperatures (typically, 30-95º C). The LCD display of FMW–9143 is capable of continuously showing many useful operating parameters such as the block temperature, the set point temperature, and the heating and cooling status. This will ensure that no other data acquisition systems or a PC is needed for the completion of the experiment. The final outcome of the calibration will be presented as a plot of temperature (or, difference in temperature) vs thermocouple e.m.f. Following are the specific objectives of this experiment:

- Make J-type thermocouples using a spot-welding machine

- Develop a typical calibration curve for a J-type thermocouple using Fluke FMW 9143 dry well facility and a standard Fluke 5609 PRT

List of equipment

- Pin Fin Apparatus

- HT15 extended surface apparatus

- HT10X heat transfer service unit

- Emissivity measurement apparatus

- Heat transfer in natural convection

- Critical heat flux measurement apparatus

- HT17 unsteady state heat transfer unit

- HT10XC computer compatible heat transfer unit

- Thermocouple spot welding machine

- Fluke FMW-9143A dry well thermocouple calibration facility

Experiments

- Heat transfer from a pin fin under forced convection heat transfer mode

- Heat transfer from an extended surface under natural convection and radiation

- Emissivity measurement

- Natural convection heat transfer for a vertical tube

- Pool boiling phenomenon up to critical heat flux point

- Unsteady state heat conduction

- Thermocouple calibration

Faculty: Dr. Umesh Madanan

Contact Person:

Mr. Farhan Babu [Lab staff]

Heat Transfer Laboratory (SL-210)

Phone: 0512-679-7987

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Critical Heat Flux Apparatus

Thermocouple Calibration System

Unsteady Conduction Equipment

Emissivity Measurement Apparatus

Pin Fin Appratus

Natural Convection Heat Transfer Appratus