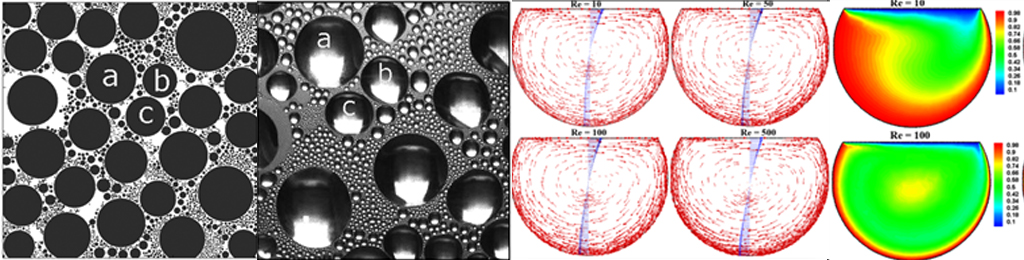

Heat Transfer

Research Areas include Liquid-Vapor Phase Change Phenomena, Heat Pipes/ pulsating Heat Pipes/ Thermosyphons, Flow and Heat Transfer in Narrow Channels, Dropwise Condensation, Energy Systems, Nanofluids.

|

|

Title of image on leftBrief description of what the image on left is about |

Card 1 Lorem ipsum dolor sit |

|

|

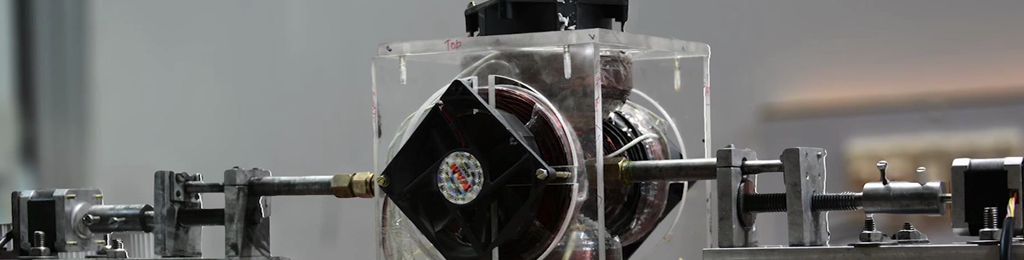

IC Engines

Major thrust areas of research are IC Engines, Combustion and Emissions, BiodieselDevelopment and Characterisation, Lubricating Oil Tribology, Laser DiagonisticTechniques and MicrosensorDevelopment for IC Engines.

|

|

Title of image on leftBrief description of what the image on left is about |

Card 1 Lorem ipsum dolor sit |

|

|

Smart Materials & Structures

The lab has extensive research areas including Active Vibration Control, Non-contact Energy Dissipation, Energy Harvesting & Energy Scavenging Sensors & Actuators, Terfenol-D, PZT and EAP based Smart Composites, Shape Memory Alloy Based Actuators, Robotic Grasping Mechanism, Space Antenna Shape Control.

|

|

Title of image on leftBrief description of what the image on left is about |

Card 1 Lorem ipsum dolor sit |

|

|

Turbomachinery

Research in this lab focuses on Computational Fluid Dynamics applied to Turbomachinery: Flow analysis through blade passages, Film cooling of turbine blades, Wake-induced unsteady flows, LES for complex transitional and turbulent flows, DNS and flow instability, Development of efficient flow solvers, Turbulence modellingof compressible flows.

|

|

Title of image on leftBrief description of what the image on left is about |

Card 1 Lorem ipsum dolor sit |

Experimental Facilities

The aim of the lab is to develop a fast, accurate and robust Navier-Stokes solver as a desired design tool for flow and heat transfer analysis through modern turbomachinery. Importance has equally been given on fundamental studies and engineering applications.

PCs & work stations networked with central computational facilities of the institute.For details please visit Computational turbomachinary

|

|