Unit Operations Lab

Through the generous donation of Rs. 1 Cr. from our esteemed alumnus, Mr. Jagjeet Singh Bindra (BT/CHE/1969), Unit Operations Lab of the Chemical Engineering Department was upgraded and state-of-the-art equipment installed. Now renamed as Jeet Bindra Unit Operations & Innovation Lab, it will provide an excellent platform for undergraduate students of the department to ideate and innovate.

Major Highlights & Activities Undertaken -

Identification of several persisting problems:

With laboratory systems and software constantly advancing, older equipment can make gathering data and storing information much more difficult. Existing old laboratory experimental set ups were designed for data collection in manual mode, thereby severely jeopardizing

- Actual visualization of various underlying processes while operating instruments.

- Accuracy and repeatability of data.

- Proper control on several experimental parameters.

- Because of robust and old design, vital sustainable alterations in some of the existing set ups were not feasible.

These problems led to serious lack of enthusiasm amongst UG students with the general consensus of the lab course being

- Obsolete and useless

- Crowded & outdated experiments confined to classical Chemical Engineering

- Lack of connection between practical applications and course theory

- Limited possibility of experiments on new frontiers of ChE.

Introducing novel & contemporary experiments:

Custom designed & automated new experimental setups enhance data accuracy, allow visualization of processes, and stimulate the young mind with novel ideas.

New Equipments in the Undergraduate Lab

| Experimental Facilities | Computational Facilities |

|---|---|

| Flow Visualization Experiment | Workstations for Simulation & Modelling: HPZ6G4 with Intel Dual Xeon 4210 Processor, 2.2GHz, 20 Cores, Intel C246 Chipset. |

| Friction Losses in Pipe Fittings | |

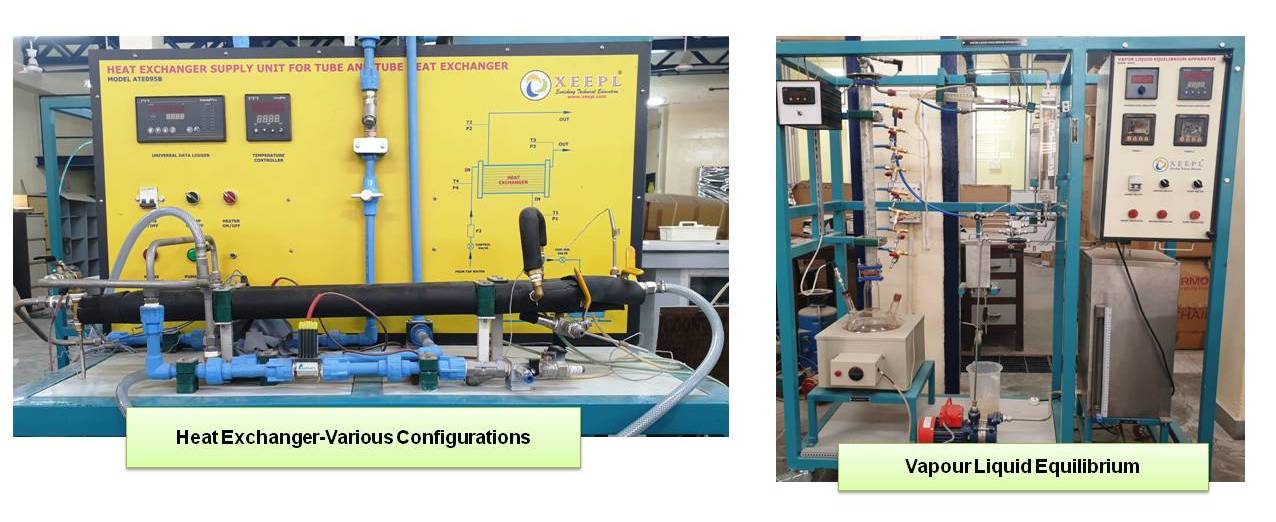

| Heat Exchanger various Models | |

| Mass transfer in Single Drop | |

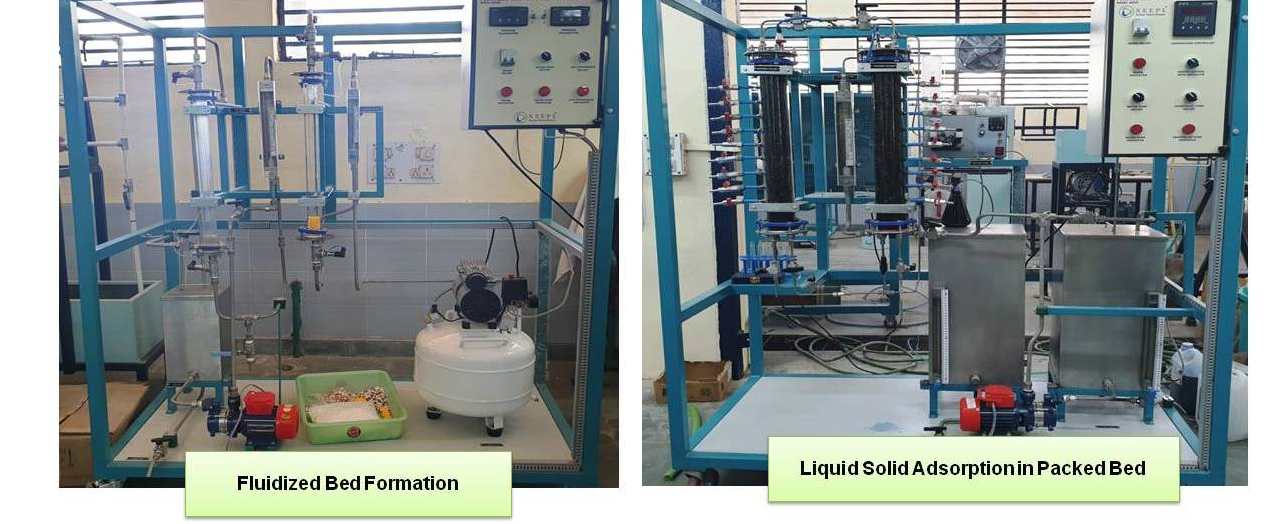

| Solid Liquid Adsorption | |

| Vapour Liquid Equilibrium | |

| Fluidized Bed | |

| Rotational Viscometer | |

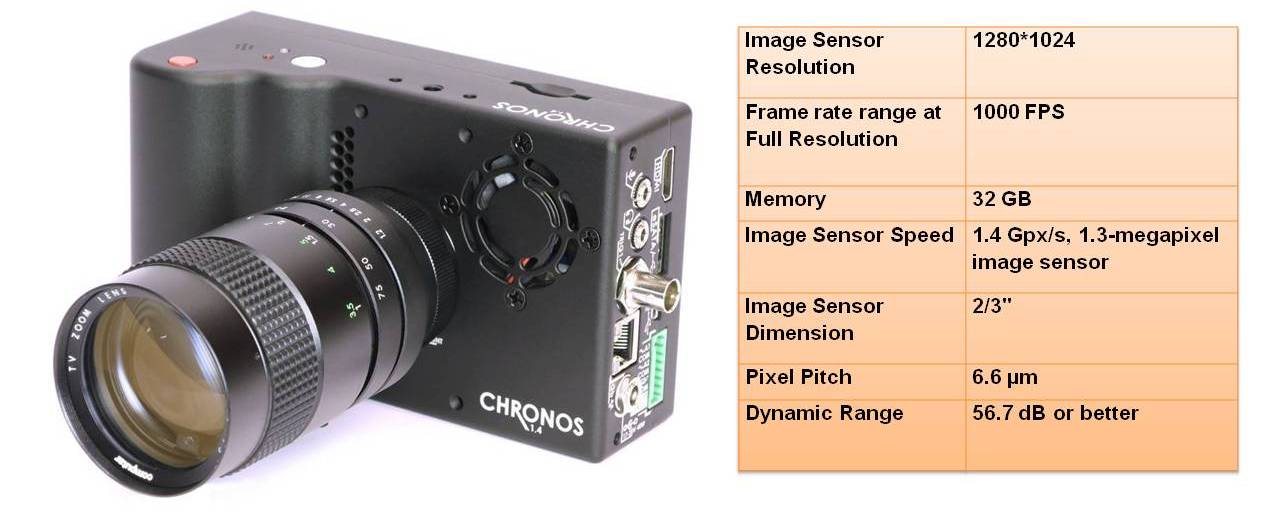

| High Speed Camera |

Snapshots of New Experimental Set-ups in JB-UOIL

Figure 1: High-Speed Camera with Frame Rate of 1000 FPS at Highest Resolution

Figure 2: Rotational Viscometer with Adaptors for Low Viscosity and Low Sample Volume

Figure 3: Experimental Set-ups on Fluid Mechanics

Figure 4: Experimental Set-ups on Mass Transfer

Figure 5: Experimental Set-ups on Heat Transfer and Thermodynamics

Upgrade of Existing Set ups in JB-UOIL Laboratory:

Up-grade in the laboratory was been undertaken keeping in mind the following aspects:

- Putting in place the right process & resources to increase scientific value while minimizing wastage of experimental time during student lab hours. For example, some of the reaction engineering setups earlier opted for a titration method for finding the conversion of the reactants into the products. An alternative, accurate & computer controlled process like the conductivity method is being now relied upon for the same experiment.

- Introducing automation in several existing set-ups ensures efficient & prudent ways of delivering superior quality results. For example, introducing data loggers in several instruments automatically helps to monitor and record environmental parameters (e.g temperature (PT100), flow rate (DPT)) over time, allowing conditions to be measured, documented, analyzed and validated.

- Ability to visualize & understand several underlying physical and chemical processes (that are taught in the UG curriculum) while performing experiments actually helps students appreciate the thought behind these experiments. For example, in the experiment "Study of Residence Time Distribution set up in CSTR and Packed bed Reactor", using acrylic-made CSTR instead of SS helps in complete flow visualization.

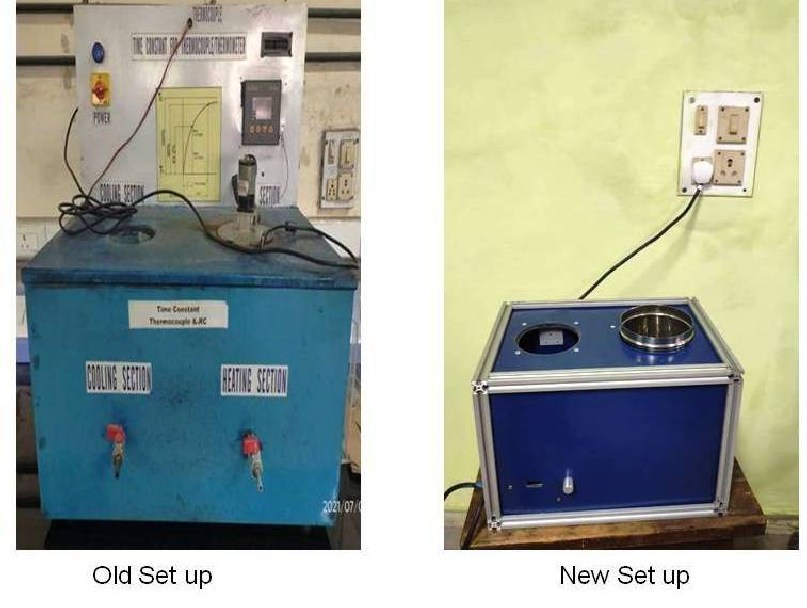

Snapshots of Upgraded Experimental Set-ups in JB-UOILJB-UOIL

Figure 6: Interacting & Non-interacting Tank System

Figure 7: RTD-CSTR and Packed Bed Reactor

Figure 8: RTD-CSTR and Packed Bed Reactor

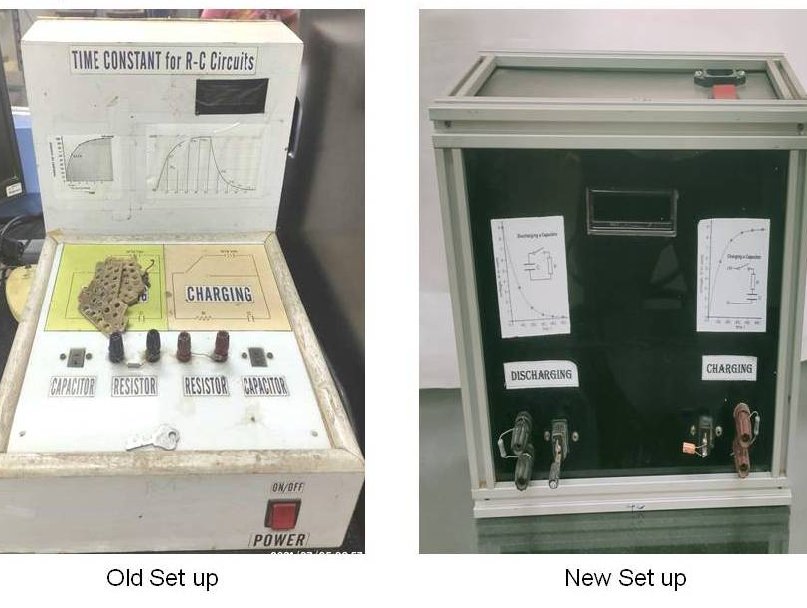

Figure 9: Experimental Set-up for Time Constant for RC Circuit

Figure 10: Experimental Set-up for Time Constant for RC Circuit

Figure 11: Newly Designed Vapour liquid Equilibrium Set-up

Impact

- The upgrade of JB-UOIL was undertaken to restructure and modernize the laboratory experience for students with new equipment and connected experiments thereby creating a more cohesive laboratory experience for the undergraduate students. Additionally, the Computational lab will augment experimental learning.

- Tying concepts learned in the lectures by providing students with hands-on laboratory experience in small teams, the JB-UOIL is the cornerstone of the curriculum. It provides an opportunity of hands-on experimentation that puts classroom learning into practice. Changes will provide students with new resources to apply the chemical engineering principles learned in their initial years. The upgrade of the lab will reinforce industry experiences and help apply textbook learning.

- To ensure that students will use laboratory equipment and experiments designed for today’s industrial reality. .

- Upgrading of the lab has ensured that IITK continues to train the best and the brightest students with the latest equipment and prepare the next generation of chemical engineers.