Process modeling

Process modeling is an important branch of metallurgical engineering and is required for optimizing the control parameters and production planning.

This is of great importance to the metallurgical industries to improve their production efficiency. Process modeling is based on the basic principles of heat and mass transport. Because of improved computational facilities, present day process modeling involves implementation of an algorithm aided by modern computers to predict the behavior of a metallurgical process under certain control parameters, which can be tuned to study their effects on overall efficiency and output enhancement. The main goal is to optimize process parameters with minimum number of actual experiments. Both forward and inverse models are commonly used. Forward modeling is used to predict the output by tuning the control parameters. On the other hand, real plant data can be collected and analyzed via inverse modeling to predict the control parameters. Shop floor automation is another important aspect of process modeling, where the ultimate aim is to design an intelligent system capable of automatically controlling the process parameters based on some internal feedback mechanism. Active research and development is under progress in our department on the above mentioned aspects of process modeling, with a special emphasis on iron and steel-making.

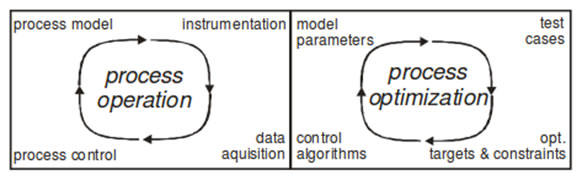

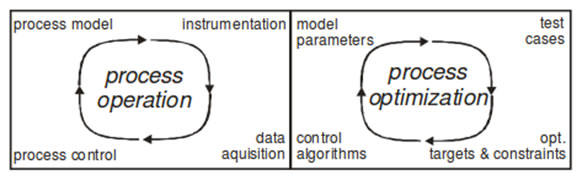

Figure-1: Various aspects of process modeling. Adopted from: J Wendelstorf: Metallurgical Process Modelling. Proceedings, SteelSim 2007,Graz/Seggau, Austria 433 (2007).