+91 512-259-6538

+91 512-259-6538

Highlighted are some of the recent publications that have emerged from our user lab facility, showcasing our commitment to advancing user-centric research and design. These publications represent just a glimpse of the impactful work happening in the ChE department using equipments of PGRL facility.

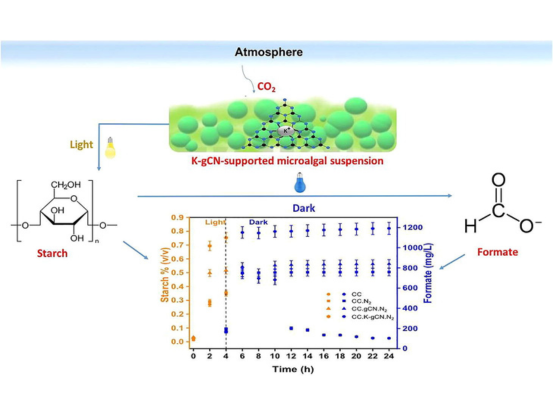

Abstract: An effective strategy to combat the adverse effects of rising CO2 levels in the atmosphere is to convert CO2 to value-added chemicals. Recently, microalgal technology has received attention for CO2 utilization considering that it provides a green pathway for producing the chemicals. The current study demonstrates the production of formate from CO2 using the Chlamydomonas reinhardtii and Spirulina microalgae. The production is enhanced using potassium (K)-doped graphitic carbon nitride (g-C3N4), a non-toxic and environmentally benign catalyst. The experiments performed in a photobioreactor show the maximum formate production over the K-g-C3N4-supported Chlamydomonas reinhardtii and Spirulina to be 1192 and 751 mg/L, respectively, which are 59 and 13 % higher than those in the corresponding uncatalyzed algal processes. Starch synthesis in the microalgae is aided by g-C3N4 in light, while potassium doping and a nitrogen blanket in the reactor increased the microalgae's ability to convert starch to formate in dark. The photocatalytic role of gCN in CO2 conversion by the microalgae was confirmed by scavenger analysis. A positive interaction between the microalgae and K-gCN was observed using the morphological and physicochemical characterization tests. Accordingly, the study confirmed that K-gCN played a dual role. It not only provided a suitable surface for the microalgae but also enhanced photocatalytic activity, which in turn improved formate production. A mechanistic insight of the step-wise conversion of CO2 to formate is proposed. In a first, this study has proposed a clean route to producing a low-carbon alternative.

Read More ...

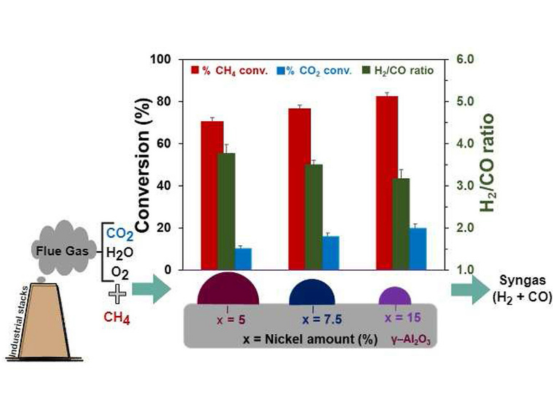

Abstract: Mesoporous Ni–Al2O3 catalysts with Ni weight (%) 5 to 15 were synthesized, characterized, and tested for tri-reforming of methane (TRM). The characterization results reveal that the metal loading influences the metal-support interaction of the catalysts. Furthermore, the choice of reduction temperature affected the dispersion of metallic-Ni. It is advantageous to reduce these catalysts at their respective temperatures, which are obtained from H2-TPR studies. At these conditions, the dispersion was maximum. For TRM at 600 °C, the conversions and yields increased with an increase in Ni loading, and carbon was not detected. Increasing the metal loading from 5 wt% to 15 wt% increased the CH4 conversion from 70.5 to 82.4% and CO2 conversion from 10.2 to 19.7%. In contrast, the H2/CO ratio decreased from 3.8 to 3.2. The conversions and yields during TRM were relatively constant with time-on-stream and were highest for 15Ni–Al. Furthermore, H2/CO ratio was >3, and minimal change in dispersion was observed post-reaction for this catalyst. Thus, the active metal loading and the reduction temperature required are important parameters that need to be considered while designing a suitable catalyst for TRM.

Read More ...

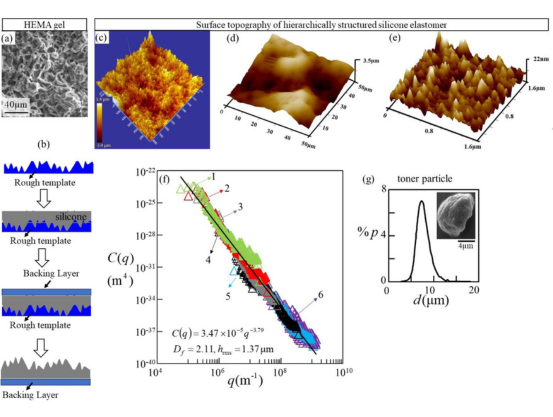

Abstract: While paper continues to remain one of the most widely used materials for writing and printing, and while its demand continues to grow, the environmental cost of using paper is rather huge. Paper is made by extracting the cellulose fibres from wood, and to meet the demand for it, large numbers of trees are felled. Making paper requires huge quantity of water, energy, and also toxic chemicals. In fact, paper is considered the 3rd largest industrial polluter of air, water, and soil. Yet a viable alternative to paper doesn't exist. Inspired by the inherent ability of many natural surfaces to keep themselves clean, we have made a reprintable paper which can be used over 50 cycles. It is prepared by casting crosslinkable silicone on a porous template, leading to hierarchical random surface features having dimensions ranging from tens of nano-meter to hundreds of micrometers. On this surface, ink particles of wide-ranging sizes and surface chemical characteristics adhere via intermolecular interactions. However, unlike conventional papers, in which particles get mechanically trapped inside the porous network of the cellulose fibres, here the ink particles remain accessible for cleaning via gentle scrubbing with a rough surface, soaked with a suitable liquid. Thus, this paper continues to remain both cleanable and printable.

Read More ...

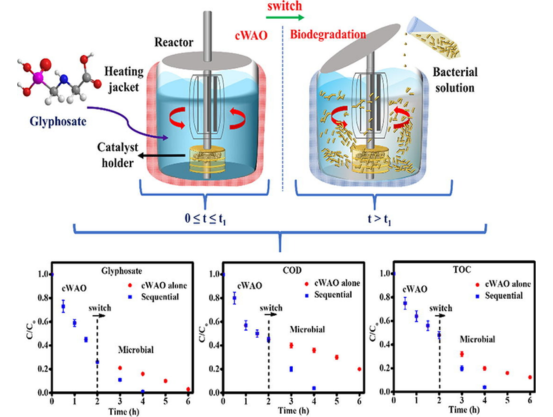

Abstract: Glyphosate, a widely used post emergence broad spectrum herbicide, recognized for its harmful impact on the environment, is sequentially mineralized in a two-step process: catalytic wet air oxidation (cWAO) followed by microbial degradation. Iron nanoparticle (Fe NP)-tipped carbon nanofibers (CNFs) supported over activated carbon beads (ACBs) are used as a cWAO catalyst. Fe-CNF/ACB with a high specific surface area (~296 m2/g), high thermal stability (25–1100 °C) and an increased exposure of the Fe NPs to the surrounding water causes ~70% degradation of the aqueous glyphosate (100 mg/L) in 2 h at 220 °C, 25 bar-air pressure, and 0.75 g/L of catalyst-dose. The residual glyphosate is, however, completely mineralized in the next 2 h at 37 °C, with 100% reduction in total organic carbon content, using a bacterium isolated from the industrial wastewater. The bacterium is phylogenetically identified as Providencia vermicola via 16s rRNA analysis. Non-toxicity of Fe-CNF/ACB towards the isolated bacterial strain eases the sequential remediation process by circumventing the necessity of removing the spent catalyst from the reaction mixture before switching over to microbial degradation. The present approach based on cWAO followed by microbial degradation is indicated to be efficient for the degradation and mineralization of toxic, biorefractory pollutants in wastewater.

Read More ...

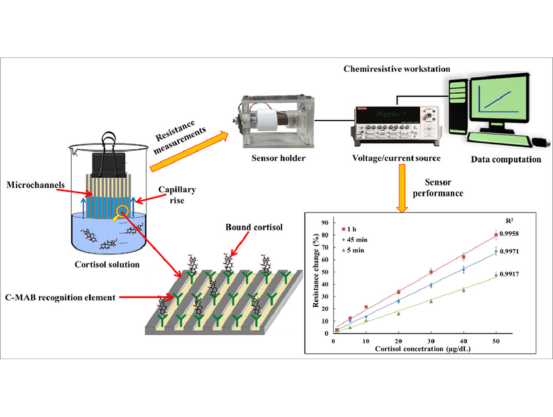

Abstract: A phenol precursor-based polymeric film (1 mm thickness), in situ impregnated with Cu and reduced graphene oxide (rGO) as the conductive fillers, is synthesised as the chemiresistive sensor for the stress hormone biomarker – cortisol. The Cu-rGO-polymeric film was engraved with microchannels (200 µm wide × 100 µm height with 200 µm interspacing) using laser ablation technique. The microchannels intensified the wettability of the film with liquid analyte and the speed of detection via capillary action-driven (passive) flow during sensing. In addition, the laser-ablated microchannels exposed the in situ dispersed Cu nanoparticles to the film surface. The surface modification of the microchannels with cortisol monoclonal antibodies, used as the recognition element, induced change in the electrical resistance of the material, corresponding to cortisol concentration. The sensor exhibited a linear response (R2 > 0.99) over the concentration range 1 – 50 µg/dL, with the sensitivity of 2.81 Ω/µg-dL−1 for a contact time of 5 min. With emerging materials and microstructural patterning, the scope of the developed chemiresistive sensor in the current study can be widened to measure a wide range of analytes.

Read More ...

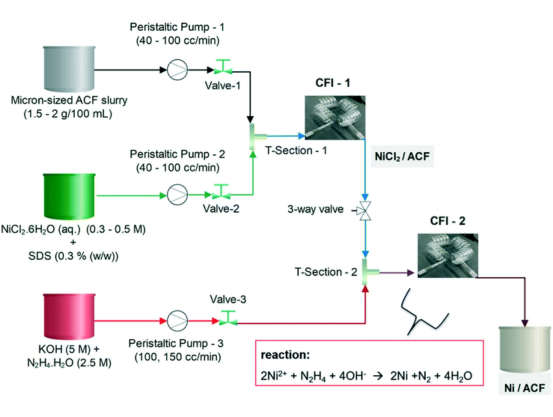

Abstract: Ni nanoparticle-dispersed activated carbon fibers (Ni/ACFs) were synthesized for the first time via a continuous flow single-stage process using a coiled flow inverter (CFI) at ∼30 °C. The process involved impregnation of an aqueous slurry of ACF with Ni-salt, followed by reduction using hydrazine, each performed separately in CFIs connected in series. Physicochemical characterization of Ni/ACF revealed Ni nanoparticles in the micropores of the substrate, with uniform elemental distributions. X-ray diffraction spectroscopy confirmed the reduction of Ni2+ to zero-valent Ni. A maximum Ni-loading of ∼564 mg g−1 was achieved using 0.5 M NiCl2·6H2O and 2 g per 100 mL ACF-dose at a flow rate of 200 cc min−1 of the Ni/ACF containing stream, which was higher than that in the conventional batch synthesis method, attributed to the flow inversion and secondary flow-enhanced mass transfer rates in CFIs. The catalytic activity analysis of Ni/ACF through two preparation reactions, namely the oxygen reduction reaction and the catalytic decomposition of acetylene to form carbon nanofibers by chemical vapor decomposition, corroborated its efficiency as a catalyst. This study has clearly provided a fast, effective, and energy-efficient method for the continuous synthesis of supported metal nanoparticle catalysts.

Read More ...

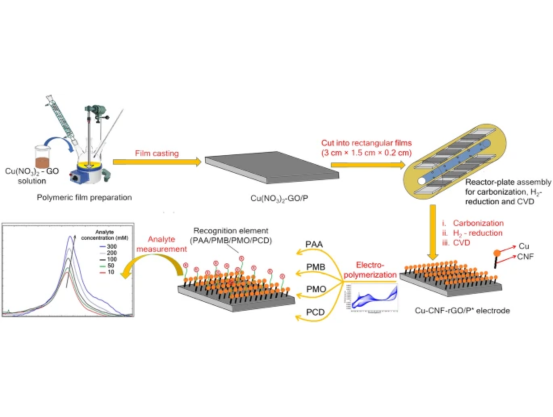

Abstract: A carbon film functionalized with reduced graphene oxide (rGO) and Cu nanoparticles (NPs)-tipped carbon nanofibers (CNFs) was demonstrated to be a versatile electrode for the efficient electropolymerization of the following monomers: acryl amide, methylene blue, methyl orange, and β-cyclodextrin. These electropolymers were used as the recognition elements for the measurements of glucose, creatinine, cholesterol, and spermine solutions, respectively. The carbon film was synthesized from a phenolic precursor via suspension polymerization and subjected to multiple thermal processes, viz. carbonization, H2-reduction, and chemical vapor deposition, in an especially designed reactor. Physicochemical tests confirmed the controlled growth of the graphitic CNFs with the electrocatalytic Cu NPs located at their tips. The CNF growth was found to be critical for providing the Faradic and electrocatalytic characteristics to the electrode, whereas rGO enhanced the material electroconductivity (462 S/m). Tested in the phosphate buffer and clinical samples using differential pulse voltammetry and chronoamperometry techniques, the prepared electrode showed a fast and reproducible response, with the limits of detection of 0.18, 0.006, 0.036 and 0.0003 mM, respectively. The synthesized Cu–CNF–rGO functionalized carbon film in this study is indicated to be a potential universal substrate for electrochemical sensors of a wide range of biomarkers.

Read More ...

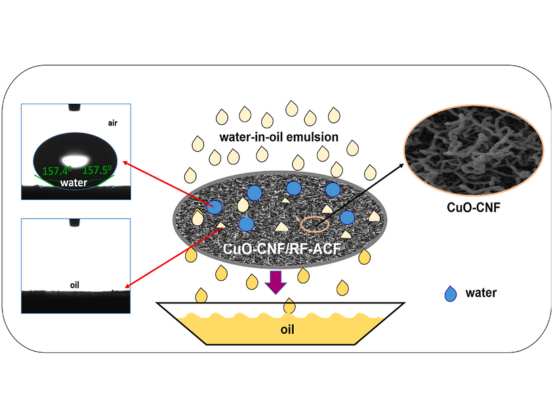

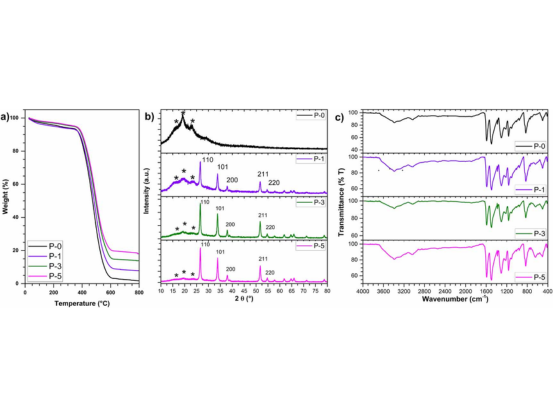

Abstract: A super-hydrophobic/super-oleophilic carbon nanofibers (CNFs)-embedded resorcinol-formaldehyde (RF)-activated carbon fiber (ACF) composite membrane is synthesized for the efficient removal of water from a water-oil emulsion. Chemical vapor deposition (CVD) with copper oxide (CuO) as the catalyst is used to form CNFs for the first time over an ACF-supported RF polymeric layer. The prepared CuO–CNF/RF-ACF membrane was physicochemically characterized as super-hydrophobic/super-oleophilic (water contact angle 157° and oil contact angle 0°), attributed to the high surface roughness (Ra ∼55.56 nm) and graphitic content of the CNFs. The membrane had an asymmetric internal structure with a hydrophobic CNF-decorated microporous surface, which facilitated oil to pass and rejection of water droplets from the emulsion. The dead-end separation test data indicated a flux of 426 ± 20 L/m2-h with the water removal efficiency of 99.7% and the permeate having water droplets with the size range of 37–78 nm when tested against a water-oil emulsion of 10% (v/v) comprising 700–1700 nm sized water droplets. The physicochemical characterization, including the tests under harsh conditions showed the material mechanically, thermally, and chemically stable. The method described in this study to synthesize CuO–CNF/RF-ACF membrane is facile and has a potential for scale-up.

Read More ...

Abstract: Metal oxide-Polyaniline (PANI) nanocomposites have shown improved gas sensing characteristics that can be attributed to the formation of a p–n junction between the n-type metal oxide and the p-type PANI. The charge transport, grain boundary depletion region, and intragrain resistance are studied to understand the gas sensing mechanism of pristine metal oxide gas sensors. However, gas sensing mechanisms for metal-oxide/PANI nanocomposites have not been studied extensively. In this work, we have studied the gas sensing mechanism of SnO2/PANI nanocomposites using electrochemical impedance spectroscopy, and temperature dependent gas sensing experiments. Well-defined SnO2 nanoclusters were observed in the PANI matrix. The n-type SnO2 was covered by p-type PANI, and a depletion region was formed at the interface. The presence of the p–n junction depletion region was confirmed by impedance spectroscopy. The polarons in PANI were trapped by NH3 leading to a change in the width of the conducting path due to rearrangement of charge carriers along the depletion region. The change in the conduction path, along with the trapped polarons, enhanced the sensor response. For higher loadings of SnO2, the depletion region was deformed, and the sensor response decreased due to non-uniform boundaries. 1 wt% SnO2 with respect to aniline precursor in in situ synthesis showed the best response of 37.8% for 100 ppm NH3 at 35 °C. The response was stable for low humidity levels up to 51%RH. The response increased for higher humidity levels. The sensor response increased from 0.17 to 2.99 upon bending 1000 times at 7.8 mm diameter due to cracks in the surface. The sensor showed only 10% variation in response after 9 months.

Read More ...

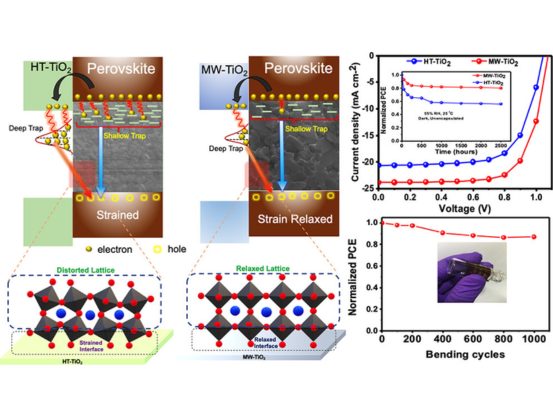

Abstract: Low-temperature (∼150 °C) solution processed planar perovskite solar cells (PSCs) using TiO2 as an electron transport layer (ETL) offer promise for a simple fabrication methodology and compatibility with polymeric substrates and perovskite-based tandem devices. However, the amorphous nature and presence of trap states on the low-temperature TiO2 surface hinder the effective carrier transport. Further, perovskite crystallization on ETL develops lattice strain resulting in the creation of unwanted defect centers. Herein, a low-temperature microwave processed compact TiO2 (MW-TiO2) film is reported that possesses lower surface oxygen vacancy defects and enhanced conductivity and promotes efficient electron extraction owing to the enhanced built-in potential (Vbi) at the MW-TiO2/perovskite interface. The suppressed heterogeneous nucleation of MAPbI3 crystals on the less defective MW-TiO2 surface relieves the interfacial strain, thereby making it a superior template for the growth of strain relaxed, high-quality perovskite films with a more n-type character having larger grains, resulting in suppressed interfacial/surface and bulk trap density. Further, MW-TiO2 mitigates the interfacial energetic disorder and Urbach energy owing to reduced strain, thereby boosting the open-circuit voltage (Voc) by 40 mV, while improved optoelectronic properties of MW-TiO2, lower interfacial charge transfer resistance, and high-quality perovskite films simultaneously improve the short-circuit current density (Jsc) and fill factor (FF) by 6.82 and 9.37%, respectively, over HT-TiO2 based devices. Compared to high-temperature (500 °C) annealed TiO2 based MAPbI3 planar PSCs, MW-TiO2 based devices exhibited a substantial performance enhancement of 22%, leading to the best efficiency of ∼18% and superior atmospheric stability (25 °C, 55% relative humidity) while maintaining 80% of its initial value after 2500 h. Experimental results are validated by device simulation studies with model accounting for trap-assisted interfacial and bulk recombination. Finally, MW processed flexible devices maintained over 80% of their initial power conversion efficiency (PCE) after 1000 bending cycles, thereby exhibiting excellent mechanical robustness. These results elucidate the critical role of MW-TiO2 in rendering improved performance, flexibility, and stability in low-temperature PSCs.

Read More ...