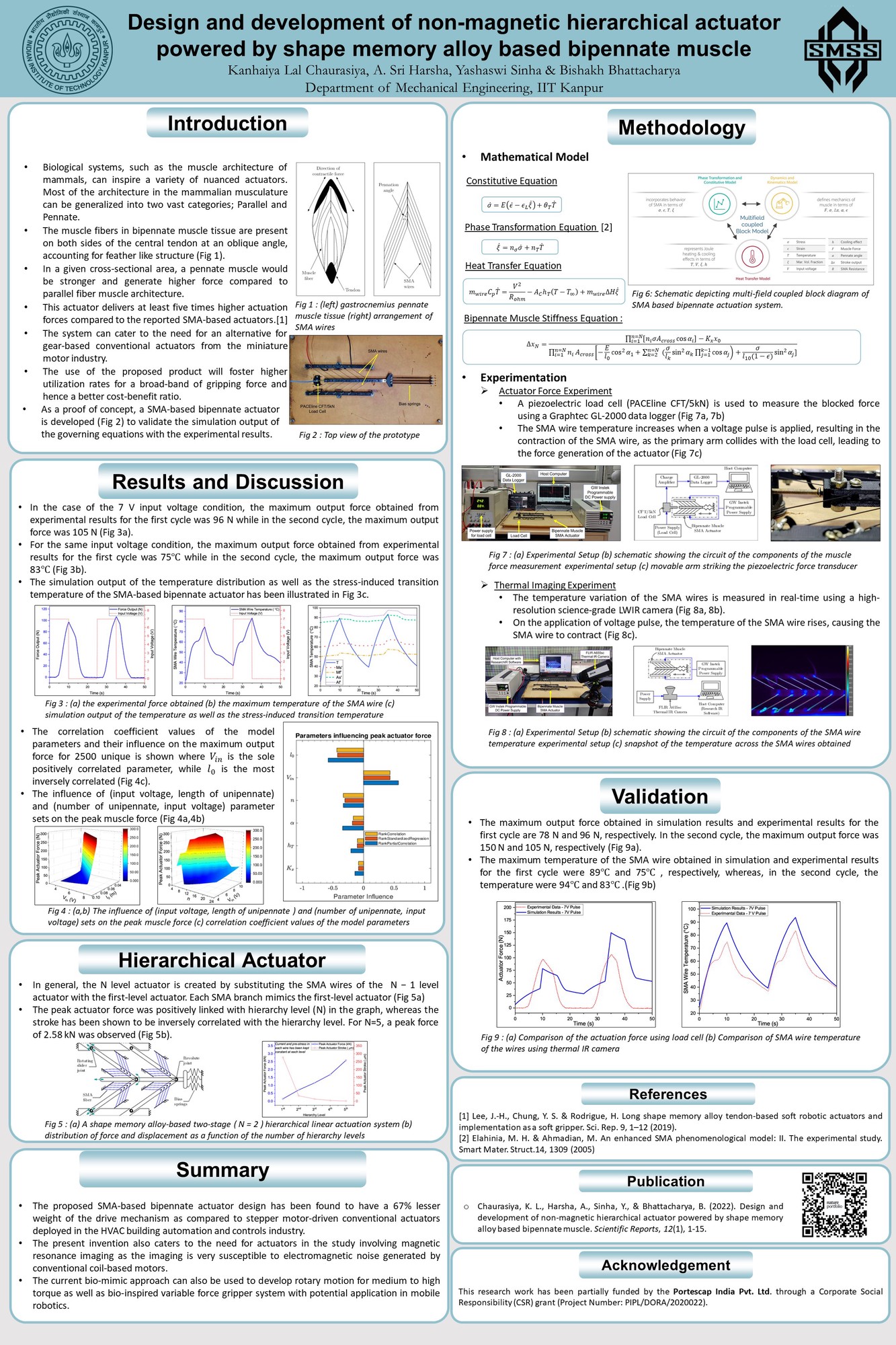

Bioinspired SMA based Actuator

- Challenge #1: DC motor based actuators are being widely used in various fields; however, they mostly depend upon the embedded gear train mechanism to provide required torque output. The use of gear trains, in turn, increases the cost, size, and weight of the actuators.

- Challenge #2: Yuan et al. (2017) reviewed shape memory alloy (SMA) based rotary actuators available and reported that their output torque capacity is limited to 1.1 N-m with a design envelope size of approximately (140 x 90 x 60 mm). The survey also reported that the overall dimension of the SMA based actuator keeps on increasing drastically with an increase in output torque requirement for a particular mechanical design.

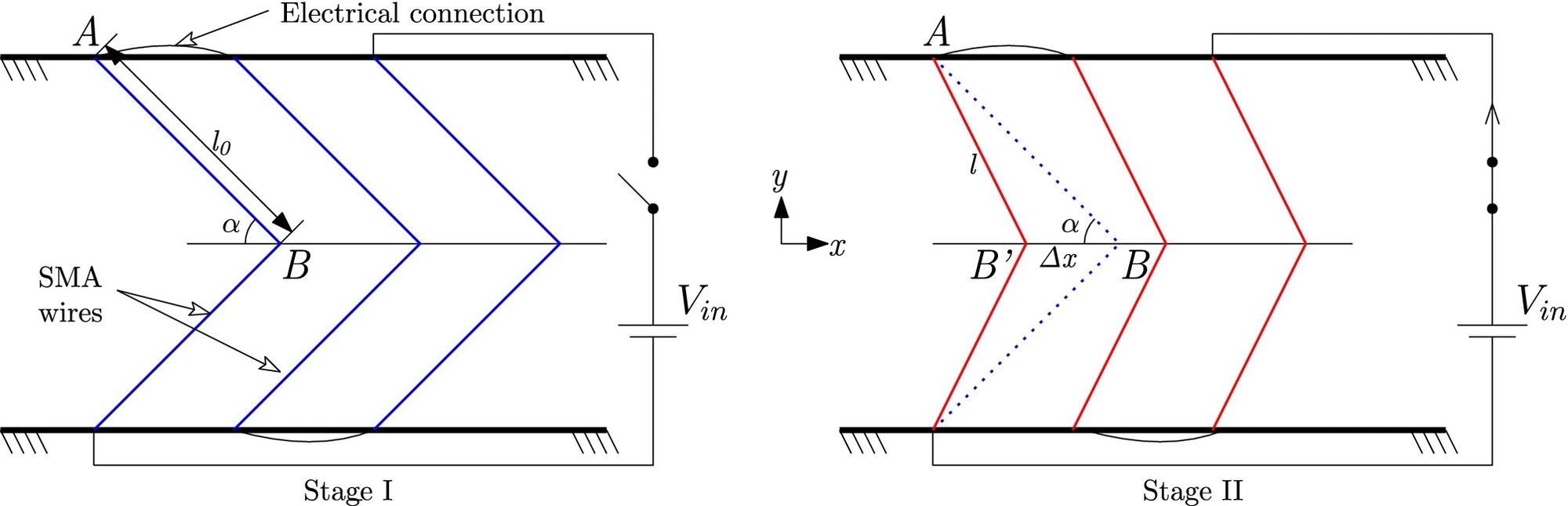

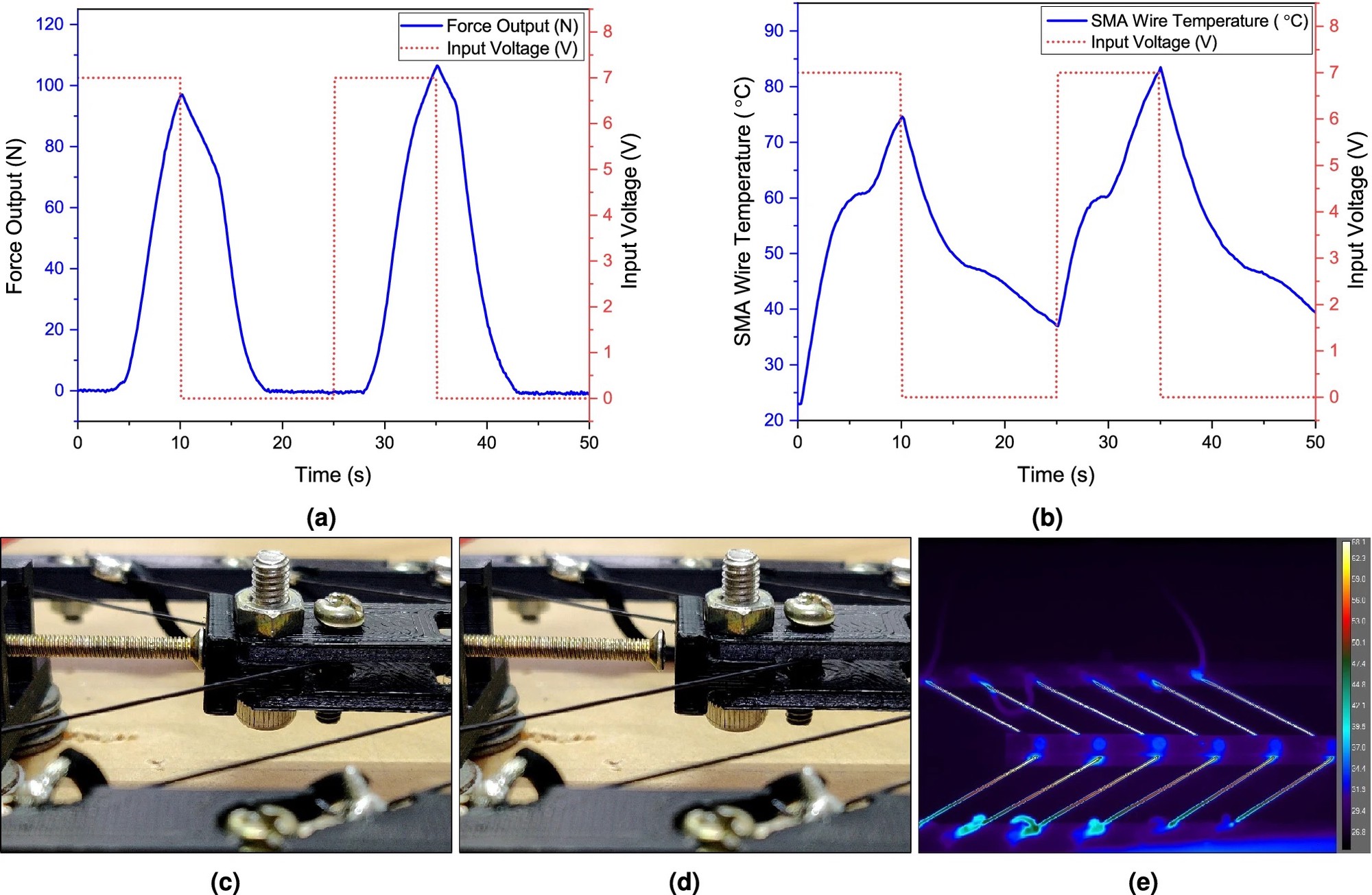

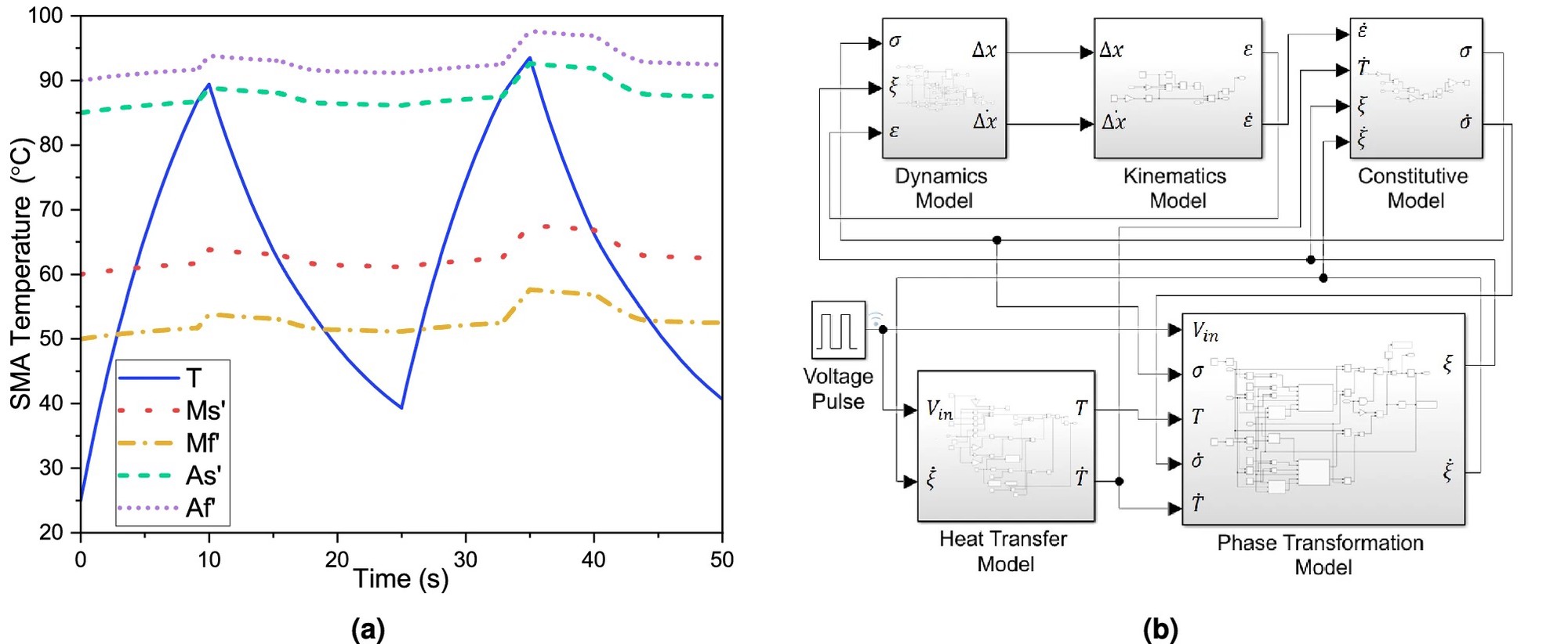

Therefore, the current project proposes to provide a solution to tackle both of the abovementioned challenges. The idea behind the project is based on the biomimetic approach, which provides an abundance of designs and solutions which are optimized and efficient in nature to solve complex human problems. The solution to this problem can be obtained from the biomimicry of muscles located in the human body. These types of muscles generally allow higher force production but a smaller range of motion. The design of muscle provides the flexibility of controlling the length of fiber (in our case, SMA wire) to obtain the torque requirement without having any significant effect on the overall dimensions, weight, and cost of the actuator.

The proposed shape memory alloy-based actuator has wide applications ranging from building automation controls to precise drug delivery methods Being in compact nature, it can also be used to control microvalves for precise drug delivery systems for cancer patients. SMA controlled actuators can be optimized towards aspects like reliability, low-cost production, safety, and minimal dimensions.

Journal Article

Patent