About the Workshop

The Indian National Academy of Engineering (INAE) has established an

expert group, led by Dr. B. Basu, Principal Engineering Investigator,

FNAE, Prof. K.A. Padmanabhan, Co-PI and former Director, IIT Kanpur, and

Dr. S. Kamat, Co-PI and DG, NS&M, to prepare a technology roadmap with

actionable recommendations for “Accelerated Materials Discovery, Scale-up

and Exploitation Strategies for Strategic Materials Needs of India”. Materials form a critical part of a nation’s progress touching all aspects

of life and industry. However, design, development, production and

deployment of materials is an expensive process involving significant

efforts, cost and time and this has been a hindrance to investments in our

country to develop new materials. There is an urgent need to address this

issue by developing technologies, capabilities and infrastructure to

accelerate materials development while reducing the cost, as well as the

environmental footprint in certain cases.

The group has identified the following five foundational proof of concept problems for engineering realization of structural / engineering

materials:

-

Advanced Steels for Critical Applications: This workstream deals with the discovery-development-deployment cycle of advanced steels for critical applications. The ICME based technology roadmap addresses twin tasks of initial alloy design and process scale-up. The discovery-development phase aims to design an alloy for critical applications that meets the target mechanical qualities, including room temperature yield strength and sub-zero temperature impact toughness. Manufacturability, repeatability, and reliability are addressed during the subsequent development-deployment phase.

-

Next Generation Super-alloys for Thermal Power Plants: Our country is engaged in the indigenous development and manufacturing of seamless tubes of alloy ASTM B983 (ASME Code Case: 2702) with India specific composition for high temperature/pressure (~720oC/310 bar and beyond) applications such as Advanced Ultra Super Critical Power Plant (AUSCPP). This workstream aims to develop an ICME based technology roadmap for accelerated indigenous development of superalloys for AUSC technology materials for current and future needs.

-

Automotive Lightweighting: This workstream aims to create a roadmap for the technology development for automotive lightweighting through weight-saving designs, materials, and manufacturing processes. The concepts feeding into the roadmap would account for end-user driving comfort, technical feasibility, scalability, manufacturability, economic viability, and sustainability. The work would envisage the use of ICME tools to develop materials to meet the lightweighting requirements that could have a secular application for both ICV and EVs. The work package would use the front-end assembly and alloy wheels as use cases to drive AI-enabled generative design and topology optimizations tools to propose design and material changes to meet the lightweighting goals.

-

Super-alloy based Component Development through PM Routes: The workstream deals with developing powder metallurgy Ni-base superalloy aero-engine turbine discs for application in advanced aircraft. It envisages adopting an ICME based approach to design a process path for a given P/M alloy composition to meet the specified target properties and performance of components of different sizes and shapes. The proposed roadmap will assist in the indigenous development of an isothermal forge press with the required capacity to forge turbine discs up to 550 mm in diameter.

-

Ti-alloy based Bio-implants: This workstream focuses on establishing Ti-based bio-medical implants as a viable replacement for steel-based implants in our country and assisting capacity-building and creating global supply chains to achieve a growth-oriented roadmap for this sector. This roadmap will identify significant issues in the Ti bio-implant development process, from raw materials to GMP-level production (product quality evaluation) to certification-related documentation, and will offer actionable advice for developing indigenous products.

One of the significant components of this project is compiling the capabilities and various tools / technologies available in India so that a roadmap with actionable recommendations may be developed. In order to achieve this goal, the ICME National Hub at IIT Kanpur, in association with INAE, is organizing an online Workshop on Capability and Tools / Technology Mapping.

Workshop Tracks and Track Coordinators

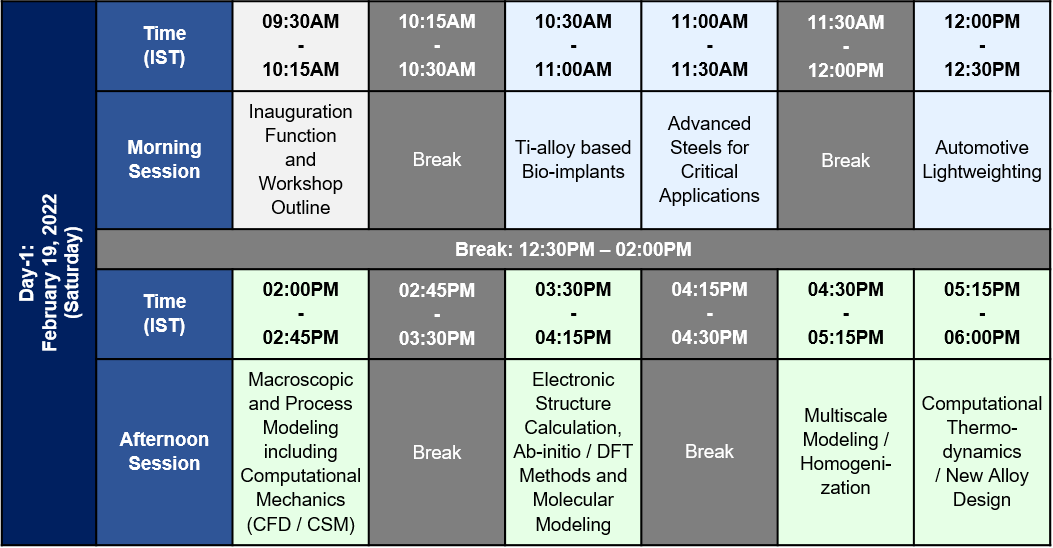

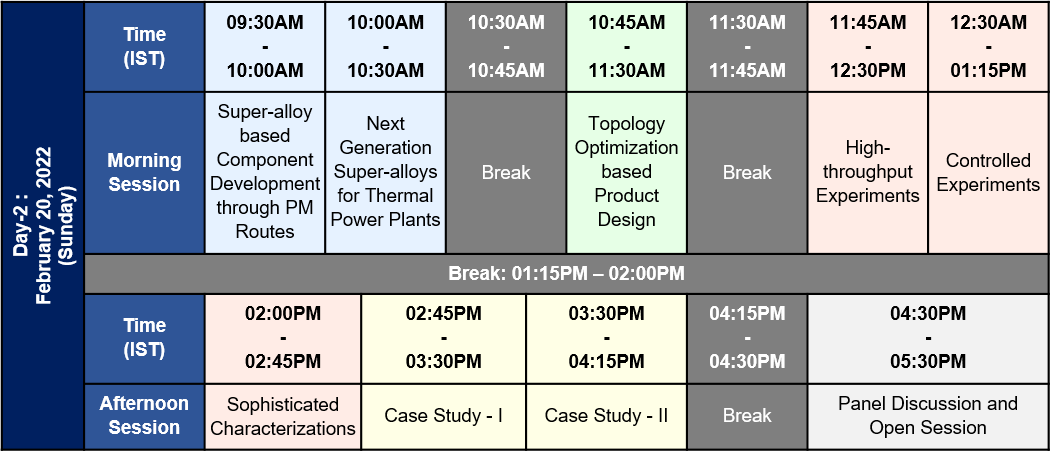

| Domains / Subject Areas | Track Coordinators |

|---|---|

| 1. Ti-alloy based Bio-implants | Dr. Partha Ghosal, DMRL | 2. Advanced Steels for Critical Applications | Dr. R. Balamuralikrishnan, DMRL |

| 3. Next Generation Super-alloys for Thermal Power Plants | Dr. Dipti Samantaray, IGCAR |

| 4. Automotive Lightweighting | Dr. K. Anand, Deakin-IIT CoE |

| 5. Super-alloy based Component Development through PM Routes | Dr. Goudu Appa Rao, DMRL |

| Modeling and Simulations | Track Coordinators |

| 1. Macroscopic and Process Modeling including Computational Mechanics (CFD / CSM) | Dr. Amarendra K. Singh, IIT Kanpur

Dr. Gerald Tennyson, TCS |

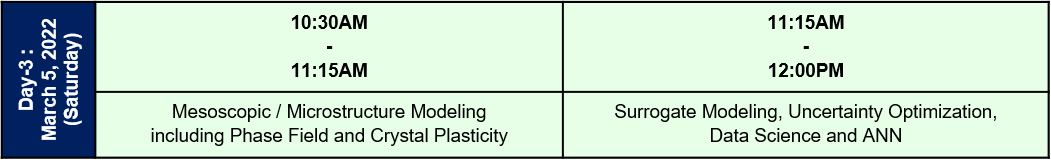

| 2. Mesoscopic / Microstructure Modeling including Phase Field and Crystal Plasticity | Dr. Pritam Chakraborty, IIT Kanpur

Dr. Abhik Choudhury, IISc Bangalore |

| 3. Electronic Structure Calculation, Ab-initio / DFT Methods and Molecular Modeling | Dr. Somnath Bhowmick, IIT Kanpur

Dr. R. Sankarasubramanian, DMRL |

| 4. Multiscale Modeling / Homogenization | Dr. Alankar Alankar, IIT Bombay

Dr. Anand Kanjarla, IIT Madras |

| 5. Computational Thermodynamics / New Alloy Design | Dr. Hari Kumar K.C., IIT Madras

Dr. A. Durga, IIT Bombay |

| 6. Surrogate Modeling, Uncertainty Optimization, Data Science and ANN | Dr. Umesh Waghmare, JNCASR

Dr. Kishalay Mitra, IIT Hyderabad |

| 7. Topology Optimization based Product Design | Dr. G.K. Ananthasuresh, IISc Bangalore

Dr. Srinivas Gunti, Mahindra Research Valley |

Experiments | Track Coordinators |

| 1. High-throughput Experiments | Dr. Nilesh P. Gurao, IIT Kanpur

Dr. Kaustubh Kulkarni, IIT Kanpur |

| 2. Controlled Experiments | Dr. Kantesh Balani, IIT Kanpur

Dr. Niraj Sinha, IIT Kanpur |

| 3. Sophisticated Characterizations | Dr. Satyam Suwas, IISc Bangalore

Dr. K.G. Pradeep, IIT Madras |

Case Studies | Track Coordinators |

| Model Integration (Horizontal Integration / Vertical Integration) | Dr. Gandham Phanikumar, IIT Madras

Dr. B.P. Gautham, TCS |

Workshop Conveners

Dr. A.K. Singh

Convener

Materials Science & Engineering

IIT Kanpur

Email: amarendra[AT]iitk.ac.in

Dr. G. Phanikumar

Co-convener

Metallurgical & Materials Engineering

IIT Madras

Email: gphani[AT]iitm.ac.in

Dr. P. Chakraborty

Co-convener

Aerospace Engineering

IIT Kanpur

Email: cpritam[AT]iitk.ac.in

Contact

Dr. A.K. Singh

Department of Materials Science and Engineering

Indian Institute of Technology Kanpur

Email: amarendra[AT]iitk.ac.in

Phone: 0512-259-6810

Mr. P. Chauhan and Dr. S. Dey

ICME National Hub

Indian Institute of Technology Kanpur

Email: icmehub[AT]iitk.ac.in

Cell: (+91) 94516 41659 / 87651 74613

ICME National Hub Website:

https://www.iitk.ac.in/ICME/

INAE Website:

https://www.inae.in/