|

Laser Micromachining |

||||

|

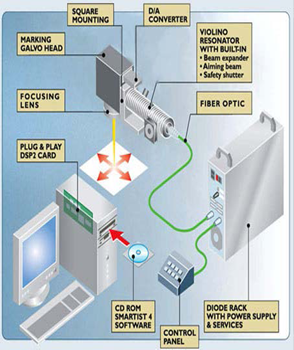

The laser micromachining (LMM) equipment can be used for engraving and creating micro-features in metallic substrates. The parts to be removed are locally vaporized using Nd:YAG laser and that vapor can be sucked with a vacuum pump. The laser micromachining equipment (V3+, laservall, Italy) is established in the Western Lab from a DST grant for the micro-fabrication lab. Basic Principle:The basic principle is similar to that of laser spot welding. The only difference is that in this equipment the mirror 3 and lens 4 are moved in such a way that the spot 5 can be moved to the required position. Unique Features:Features ranging from 50 μm to 1mm can be created very easily. The shapes that are difficult to manufacture using conventional machining can be created easily using LMM equipment. |

||||

|

Location: |

||||

|

Department of Chemical Engineering, |

||||

|

Contact: |

||||

|

Prof. Deepak Kunzru This email address is being protected from spambots. You need JavaScript enabled to view it.

|

||||

|

Figure: 1 |

||||

|

Figure: 2 |

||||