Wettability of Ultra High Molecular Weight Polyethylene – Hydroxyapatite- Aluminum Oxide -Carbon Nanotubes Composites

Dr. Kantesh, Department of Materials Science and Engineering

Surface properties such as wetting behavior, surface free energy, and its polar- and dispersion- components significantly affect the end use of the material in numerous ways. Some of the examples are hydrophilic nature of implanted material facilitates the cell adhesion, high surface energy improves the spreading of liquid ink in printable electronics, adsorption behavior of packaging material in food packaging industry is the issue of reliability etc. Therefore, it is necessary to evaluate the surface properties of engineering materials. Ultrahigh molecular weight polyethylene (UHMWPE), invented in 1962 are continuously in use as articulating surface in total hip and knee joint replacement [1]. UHMWPE based polymer-ceramic hybrid composites are being developed to enhance long term durability/wear resistance property of these articulating surfaces [1-4]. Addition of reinforcement phases alters the desired response of the material. Therefore, systematic wetting study on hydroxyapatite (HA), Al2O3 and carbon nanotube (CNT) reinforcements were carried out on UHMWPE-HA-Al2O3-CNT composites. HA, Al2O3 and CNT reinforced UHMWPE composites were prepared using compression molding at the pressure of 7.5 MPa, temperature 180°C and holding time 60 minutes. Designation system used for the developed composites has been elicited as UxHyAwCz, here x,y,w and z are the wt.% of UHMWPE, HA, Al2O3 and CNT, respectively. These composites were polished to the same roughness level to analyse the wettability behaviour using DataPhysics Tensiometer (Model OCA EC15) at room temperature. Images of sessile drop on composite surface shown in Fig. 1 evinces the combined effect of Al2O3 and CNT, and elicits enhanced contact angle (by ~370) compared with the surface of UHMWPE matrix reinforced with HA due to the superhydrophobic nature of CNT.

Wettability nature of material is also affected by the surface chemistry (or surface energy). Hence, it is necessary to obtain the surface energy and its component to get an insight of wetting nature. Owens-Wendt-Rabel-Kaelble method was utilized to measure the surface free energy (SFE) of composites and their polar and dispersion parts using the following equations (1-5)[6].

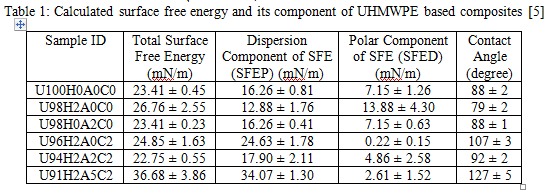

Here, σs, σl are surface energy of the solid surface and surface tension of the liquid used, respectively.σsl is the interfacial tension between the drop and the solid, θ is the contact angle on the solid surface. σsd and σsp stand for the respective contributions of the solid, while σld and σlprepresent the disperse and polar parts of the liquid. Calculated values are tabulated in Table 1. The values obtained from equations (2-4) are substituted in equation (1). Linear regression method is used to fit the unknown quantities to obtain surface energy of solid surfaces using eq. (5) and summarized in Table 1.

An important conclusion can be drawn from Table 1 that dispersion fraction of composites enhances with Al2O3 and CNT addition while the polar component of surface free energy increases with HA addition. It is also worthy to mention here that polar and dispersion component of surface free energy plays a significant role in wetting and protein adsorption, instead of total free energy or chemistry of surface alone.

Keywords: Compression molding, Biomaterials, Contact angle tensiometer, Surface energy

References

ADDIN EN.REFLIST [1] S.R. Bakshi, K. Balani, T. Laha, J. Tercero, A. Agarwal, JOM (2007) 50-53.

[2] L. Fang, Y. Leng, P. Gao, Biomaterials 26 (2005) 3471-3478.

[3] L.M. Fang, Y. Leng, P. Gao, Key Engineering Materials 334-335 (2007) 701-704.

[4] J.F. Gao, Z.M. Li, Q.J. Meng, Q. Yang, Mater Lett 62 (2008) 3530-3532.

[5] A. Gupta, G. Tripathi, B. Basu, K. Balani, JOM (in press) (2012).

[6] D.K. Owens, R.C. Wendtn, Journal of Applied Polymer Science 13 (1969) 1741-1747.